ENVIRONMENT

Key Elements

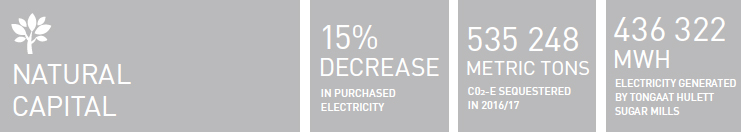

Reduced emissions by 1 percent

Eight consecutive years of participating in CDP Carbon, 4 years in CDP Water

Improvement in Water Resources Management

Key priorities going forward

Improving soil health and promoting sustainable agriculture

Energy efficiency

Emissions reduction

Smart irrigation solutions

With the increasing demand to grow more food, the responsibility lies with agriculture and agri-processing businesses to look after the soil in areas in which they operate. Since healthy soil forms the foundation of food production in successful agriculture, unproductive soil can be rehabilitated through the adoption and implementation of more environmentally friendly approaches. This is promoted by the three main interlinked principles of Conservation Agriculture: minimal soil disturbance, permanent soil mulch cover and crop diversification.

CLIMATE CHANGE

According to the United Nations Food and Agriculture Organisation, there is no doubt that climate change impacts food security. Overhauling farming and food systems will be complex due to the vast number of stakeholders involved, the multiplicity of farming and food processing systems and differences in ecosystems. The effects of climate change on agricultural production and livelihoods will vary across countries and regions. Tongaat Hulett recognises the need to adapt to the physical impacts of climate change, which may affect operations, particularly through the availability of water and the occurrence of extreme weather events. The company continues to engage with experts on several innovative initiatives, including programmes to improve irrigation efficiency and more drought-resistant crop varieties.

Sub-Saharan Africa will experience the largest increase in the number of poor, partly because its population is more reliant on agriculture. Therefore, success in transforming food and agricultural systems will largely depend on supporting smallholders in adapting to climate change. Tongaat Hulett relies on agricultural products produced in greatly varying agro-ecological and socio-economic conditions. Solutions are tailored to these conditions, but overall, significant improvements in food security, as well as resilience to climate change is achieved by introducing sustainable agricultural practices.

Tongaat Hulett’s approach to dealing with the impacts of climate change includes increasing resource-use efficiency, cutting fossil fuel usage and avoiding direct environmental degradation, enhancing productivity sustainably and reducing dependence on external inputs. Improved crop production and fertiliser management offer the greatest potential to reduce nitrous oxide emissions, while also reducing input costs. Increasing stocks of soil organic carbon improve crop yields and build resilience to drought and flooding, but also sequester carbon. The company participates in public environment fora and, during the past year, this included Business Unity of South Africa (BUSA), the Industry Task Team on Climate Change (ITTCC), parliamentary discussions and the Department of Environmental Affairs (DEA) on Carbon Budget and Carbon Tax alignment.

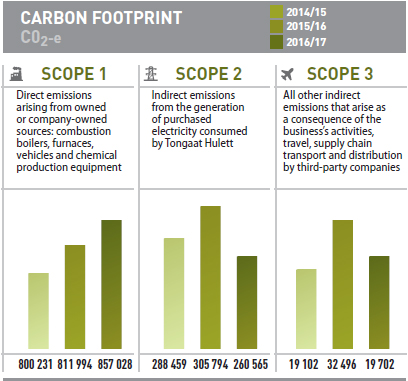

CARBON MANAGEMENT

As part of its broader response to climate change, Tongaat Hulett participated in the CDP (formerly Carbon Disclosure Project) for the eighth consecutive year. The CDP is an independent initiative that encourages transparency on climate change-related issues, with an emphasis on emissions disclosure. The company’s carbon footprint analysis was conducted per the Greenhouse Gas (GHG) Protocol, published by the World Business Council for Sustainable Development (WBCSD) and the World Resources Institute and has reported Scope 1 and 2 GHG data in compliance with ISO14064:3. Terra Firma Solutions has provided limited assurance on Scope 1 and 2 GHG data in accordance with ISO14064:3. Details of the company’s current actions are provided in the public response to the CDP, available at www.cdproject.net. Tongaat Hulett tracks and monitors its GHG emissions, seeking through ongoing efforts to improve the accuracy and reporting of its carbon footprint.

During the year, business operations emitted 857 028 metric tons of CO2 equivalent (CO2-e) Scope 1 emissions (2015/16: 811 994). The company purchased electricity that emitted 260 565 metric tons of CO2-e (2015/16: 305 794). The total Scope 3 emissions were 19 702 metric tons CO2-e covering business travel, comprehensive supply chain transport and distribution by third-party companies (2015/16: 32 496). In the 2016/17 reporting period, employees booked 7 274 business trips, flying more than 5,675 million kilometres, resulting in 1 067 metric tons CO2-e being emitted from business travel. The total Scope 1, Scope 2 and Scope 3 carbon emissions for the period under review was 1 137 295 metric tons CO2-e and the turnover was R17,915 billion, which equates to 63 grams of CO2 emitted per Rand generated. The GHG emissions have been verified by a third-party service provider.

Overall, there was a 1 percent decrease in emissions from the previous period, a 15 percent decrease in purchased electricity due to improved weather conditions resulting in less irrigation, and a 39 percent decrease in Scope 3.

Overall, there was a 1 percent decrease in emissions from the previous period, a 15 percent decrease in purchased electricity due to improved weather conditions resulting in less irrigation, and a 39 percent decrease in Scope 3.

Total emissions from South African operations, calculated at 712 015 metric tons CO2-e, includes emissions of 404 215 metric tons CO2-e emanating from the South African sugar operations. Tongaat Hulett completed a study with the assistance of global carbon experts, which found that the company’s sugar farms sequester carbon at a rate of 12 tons per hectare per annum from sugarcane produced. Using this rate, Tongaat Hulett’s 44 604 hectares (grown from company-owned and leased land) equates to 535 248 metric tons CO2-e sequestered in this financial year. The South African sugar operations could benefit from the carbon capture and storage of CO2 in the growing of sugarcane if the National Treasury allows for sequestered emissions to be deducted from the company’s carbon footprint. Therefore, 176 767 metric tons would have been subject to carbon tax in this financial year.

ENERGY

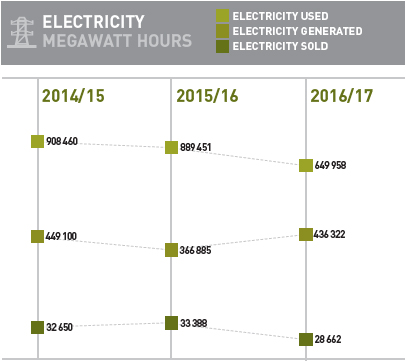

Energy efficiency is one of the regions challenges compounded by the need for an affordable, sustainable energy supply. The most practical and immediate route to success is not the building of new power-generating plants, but the use of less energy from the national grid. Eskom has long called for a voluntary 10 percent reduction by users to assist with the balance of electricity supply and demand, particularly at peak periods. It will take years for the government-backed utility to commission enough new power stations to cater for the backlogs in supply. The introduction of a suitable regulatory framework for the provision of privately-produced alternative electricity to the national grid in South Africa could potentially result in Tongaat Hulett expanding the business’s ability to generate electricity from bagasse, a renewable resource produced as a co-product of the sugar production process. In the short to medium term, this would involve infrastructure development projects across the company’s sugar mills to significantly increase electricity generation from bagasse.

Energy efficiency is one of the regions challenges compounded by the need for an affordable, sustainable energy supply. The most practical and immediate route to success is not the building of new power-generating plants, but the use of less energy from the national grid. Eskom has long called for a voluntary 10 percent reduction by users to assist with the balance of electricity supply and demand, particularly at peak periods. It will take years for the government-backed utility to commission enough new power stations to cater for the backlogs in supply. The introduction of a suitable regulatory framework for the provision of privately-produced alternative electricity to the national grid in South Africa could potentially result in Tongaat Hulett expanding the business’s ability to generate electricity from bagasse, a renewable resource produced as a co-product of the sugar production process. In the short to medium term, this would involve infrastructure development projects across the company’s sugar mills to significantly increase electricity generation from bagasse.

For the year ended 31 March 2017, Tongaat Hulett used a total of 649 958 MWh (2015/16: 889 451 MWh) of electricity across all its operations and offices. It generated 436 322 MWh (2015/16: 366 885 MWh) from its sugar mills, predominantly from bagasse, and sold 28 662 MWh (2015/16: 33 388 MWh) to the national grid. Other sources of fuel that are used include coal 300 268 tons (2015/16: 282 885 tons), diesel 10,9 million litres (2015/16: 12,7 million litres), petrol 0,857 million litres (2015/16: 0,994 million litres), gas 472 349 GJ (2015/16: 492 397 GJ) and wood.

AIR QUALITY

AIR QUALITY

The deliberate strategy of burning bagasse ahead of coal as a fuel by sugar mills significantly improves the quality of emissions in terms of particulate matter, noxious gases, and carbon and sulphur oxide. Wet scrubbing technology continues to be used by most operations to remove fly-ash from the flue gas to ensure that emissions meet acceptable air quality standards. Tightening regulatory constraints and changing societal expectations in relation to air emissions present challenges and opportunities for the business. While some emissions will always be inevitable because of the very nature of manufacturing operations, the company realises the need to improve performance. The primary use of coal as a fuel to fire boilers at the refinery in South Africa presents challenges in improving the quality of emissions. To address this, the company has developed an improved process technology solution which could be applied at that operation. The execution of the first phase of this process technology solution is expected to take place during 2017. This technology implementation is aligned with the refining operation's commitment to reducing emissions and achieving its compliance objectives as agreed with the authorities.

BIODIVERSITY AND LAND MANAGEMENT

Soil health plays a critical role in maintaining biodiversity. Experts warn that 33 percent of world soil is already moderately to highly degraded due to erosion, nutrient depletion, acidification, urbanisation, and chemical pollution, putting future supplies of food, water and energy at risk. Tongaat Hulett continues to rehabilitate currently unproductive land to agriculture, while also securing additional sugarcane supply to its mills.

A total of 7 709 developable hectares of land in KwaZulu-Natal has been identified for conversion, at the appropriate time, in support of growth and development of the region. This conversion is carefully managed and coordinated in line with broader government objectives and spatial policies. A major element of this conversion includes the rehabilitation of the affected ecological systems through a range of biodiversity improvement practices.

The business works to avoid and minimise biodiversity loss and land disturbance, while improving its biodiversity management practices. This approach, which has been well established over many years, focuses on implementing the mitigation hierarchy of avoidance, minimisation, restoration, and offsets where appropriate.

WATER RESOURCE MANAGEMENT

WATER RESOURCE MANAGEMENT

Water is an essential input in the business, all operations are affected by uncertainties and challenges associated with water consumption. According to the 2030 Water Resources Group projections, without improvements in the way water is managed and used, the world could face a 40 percent supply gap by 2030. It is for this reason that the business is using the Water Risk Filter Tool to assess the water risk exposure to share in the implementation of sound water stewardship strategies at the watershed level.

To this end Tongaat Hulett is partnering with other stakeholders in the uMhlathuze Water Stewardship Programme. The uMhlathuze region of the Pongola-Umzimkhulu Catchment Management Area is facing significant water stress. This is significantly impacting economic activity and livelihoods, particularly within the Richards Bay industrial complex and is also affecting agricultural and forestry activities in the middle and upper reaches of the catchment. In the context of the critical drought situation in South Africa, the uMhlathuze is one of the most affected areas.

NEED FOR COLLECTIVE ACTION AT SCALE

It is recognised that businesses, landowners, government and civil society are already collaborating on water-related risk mitigation through other fora, primarily around the Richards Bay area. However, these efforts do not consider the need for collective action at the catchment scale, or to unlock resources and action from national and international parties to assist in efforts in the catchment. These and other parties in the uMhlathuze region therefore recognise the need for focused and immediate collective action to facilitate improved water resources management by all relevant stakeholders, resulting in improved water security for all water users. Stakeholders include the Department of Water and Sanitation; KwaZulu-Natal, Deutsche Gesellschaft für Internationale Zusammenarbeit GmbH - International Water Stewardship Programme, Grindrod, Mondi South Africa Division, National Business Initiative (NBI), Pongola Umzimkhulu Proto Catchment Management Agency, Strategic Water Partners Network, Tongaat Hulett, Transnet and WWF South Africa.

As an agriculture and agri-processing business, water is a vital part of Tongaat Hulett’s daily operations. Climate change, with its consequent impacts on water availability and water quality, continues to impact on several the regions in which Tongaat Hulett and its suppliers operate. Water pollution has the potential to increase operational costs and compromise the quality of products. It is therefore in Tongaat Hulett’s interest to ensure sustainable management of shared water resources in the regions where it operates and procures.

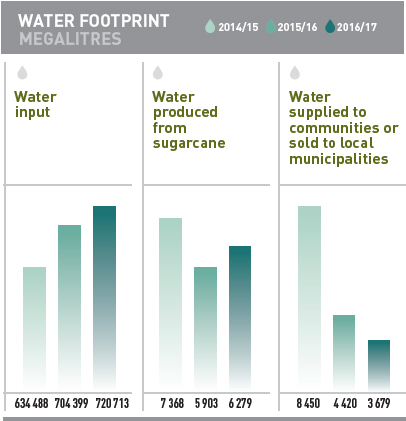

Input water sources include water abstracted from rivers, water available in sugarcane and water purchased from municipal sources. Most sugar mills operate in remote locations and therefore assist in the provision of potable water to local communities. For the reporting year ended 31 March 2017, the total water input was 720 713 megalitres (2015/16: 704 399) of which 6 279 megalitres (2015/16: 5 903) was produced from sugarcane and 3 679 megalitres (2015/16: 4 420) was supplied to communities or sold to local municipalities. Overall, there was a 2 percent increase in water input.

Input water sources include water abstracted from rivers, water available in sugarcane and water purchased from municipal sources. Most sugar mills operate in remote locations and therefore assist in the provision of potable water to local communities. For the reporting year ended 31 March 2017, the total water input was 720 713 megalitres (2015/16: 704 399) of which 6 279 megalitres (2015/16: 5 903) was produced from sugarcane and 3 679 megalitres (2015/16: 4 420) was supplied to communities or sold to local municipalities. Overall, there was a 2 percent increase in water input.

EFFLUENT MANAGEMENT

A philosophy of "target zero effluent" disposal is subscribed to across all operations. It is understood that it entails a journey involving upgrading production processes and infrastructure and shifting operational culture, aiming to reduce effluent discharge as a priority before treating and reusing the minimal amount that must be discharged. The quality of effluent being discharged is subjected to ongoing internal and third-party monitoring processes to ensure it meets minimum specifications set by statutory authorities. Water that is produced as part of the sugar milling process is largely used for the irrigation of sugarcane on adjacent estates while effluent produced at the central sugar refinery is disposed of into the municipal sewer for treatment. The quantity and quality thereof is monitored to ensure compliance with the relevant specifications. The remaining mills are progressing with environmental management programmes to adopt best practices and ensure legal compliance as a minimum.

The Maidstone mill, in South Africa, is currently developing a Request For Proposal for the building of an effluent treatment plant, to treat effluent to the standard required for discharge to watercourses.

WASTE MANAGEMENT

In line with the "ZERO HARM" principle, Tongaat Hulett manages waste from its operational processes with a "target zero hazardous waste" mindset. Efforts are directed towards reducing the amount of hazardous waste being generated. Waste management plans follow a hierarchy of control steps to reduce, re-use and recycle waste before earmarking for ultimate disposal. Operations based in South Africa, Mozambique, Botswana, Namibia and Swaziland make use of registered waste companies that collect non-valuable hazardous waste from operations and dispose of it at designated hazardous landfill sites. Zimbabwe-based operations have constructed hazardous disposal sites that are registered by the regulatory authority and are subject to annual statutory and third-party audits.

During the reporting period 2016/17, 10 209 tons of general waste (2015/16: 10 387 tons), 3 080 tons of scrap metal (2015/16: 2 486 tons) and 413 tons of hazardous waste (2015/16: 763 tons) was generated and disposed of in accordance with applicable legislation.

ENVIRONMENTAL INCIDENTS AND COMPLIANCE

The company responded to most concerns raised by affected stakeholders, mainly from surrounding communities. There were no serious incidents or non-monetary sanctions for non-compliance with applicable environmental regulations registered during the year under review. The established community liaison forums between Tongaat Hulett and interested parties continue to address environmentally-related complaints.

There were no Level 2 or 3 environmental incidents nor complaints recorded in the year (2015/16: 2 Level 2 Incidents; 0 Level 3 Incidents). A total of 425 Level 1 incidents were recorded (2015/16: 416) while 142 Level 1 complaints were registered and attended to (2015/16: 92). Most Level 1 incidents were related to vandal fires (in sugarcane fields) and illegal dumping incidents perpetrated by unidentified members of the public. There were also incidents/complaints of dust, environmental noise and effluent smell particularly at Maidstone mill. At Starch operations, Level 1 environmental odour complaints were recorded related to nuisance odour often experienced during plant start-up or stoppages.

Operational processes were adjusted to improve odour emanating from production processes. At Tongaat Hulett Sugar Maidstone mill, purging of the system with lime and keeping to irrigation times reduced the odour complaints but these were also weather dependent. Environmental noise at the same operation was caused by malfunctioning of equipment, which was repaired. The impact of dust from all operations is monitored through dust fall out processes. The plan that was previously committed to refurbishing feed dryers at Tongaat Hulett Starch Kliprivier mill was completed in July 2016 and optimisation of dryer operation after installation was also completed.