CHIEF EXECUTIVE'S REVIEW

Peter Staude

Chief Executive Officer

Profit from operations of R1,691 billion for the fifteen month period ended March 2010 reflected an increase of 28 percent over the corresponding period, with headline earnings improving by 37 percent to R858 million (March 2009: R626 million). Tongaat Hulett has increased profit from continuing operations every year since 2003 as the company benefits from its growing operations and the emerging favourable global dynamics for glucose, starch, sugar, renewable energy and land.

The 2009/10 period was an eventful one which included the commissioning and first cane harvests of the R1,63 billion Xinavane and Mafambisse agricultural and milling expansions in Mozambique. In Zimbabwe, the re-introduction of relevant economic fundamentals into the Zimbabwean economy and business sector and, in particular, the introduction of the US dollar as the economic currency, has lead to the restoration of business fundamentals. The South African sugar operations results were affected by increased competition for cane, adverse weather conditions, the impact of land reform and inadequate re-investment in sugar cane farming operations.

During the period good progress was made on developing detailed plans for the horizontal and vertical expansion of sugar cane in all regions in which the company operates. These plans will enable the company to increase sugar production from 1,0 million tons in 2009/10 to in excess of 1,9 million tons and enhance shareholder returns.

Business activities during the period were affected to some extent by the effects of the global financial crisis on consumer and property markets. In the starch operation lower local market demand was offset by the benefits of the improved local maize and international starch and glucose markets and the various advances made over a number of years. The continued expansion of eThekwini and the need to provide the necessary infrastructure to support community developments, constraints imposed by the city’s topography and the extensive government investment in infrastructure, most notably the recently opened King Shaka International Airport, is seeing the city expand towards the region north of eThekwini. During the period, Tongaat Hulett continued to collaborate with government and municipalities in the conversion of land for new housing and employment opportunities and the associated social infrastructure and successfully concluded land sales in the eThekwini growth corridor, in a market environment where conditions deteriorated in the prime residential, resorts and commercial sectors.

As the attention on climate change continued to increase, the recent Copenhagen climate change talks whilst disappointingly not being able to reach agreements and commitments on specific emission reduction targets, did acknowledge and reach consensus on the need to limit global emissions and provide funding to finance climate action in developing countries. In Southern Africa, the regulations surrounding climate change and renewable energy are in their infancy and have inhibited the development of cogeneration of electricity and biofuels.

During August 2009, Anglo American disposed of its 50 percent stake in Tongaat Hulett in a book build equity process. The process demonstrated strong demand from both local and foreign institutional investors for Tongaat Hulett shares with the improved liquidity and access to the shares being positive for shareholders. In order to align the financial reporting of the business with the significantly increased contribution of the agriculture and agri-processing components of the business, the financial year end has changed to the end of March.

Tongaat Hulett follows a philosophy of sustainable development and continued to make good progress in entrenching and enhancing the various programmes and initiatives it has in place in the areas of safety, health, environment and community relationships. This is consistant with the requirements of the King III corporate governance framework, including ensuring that sustainability matters are an integral component of the company’s strategy. The detailed sustainability report for the period, in which the specific details of each programme are addressed, is included as part of this integrated annual report.

The safety and the welfare of all employees is a key priority as the company strives to create a workplace free of injuries. All areas of the business continue to focus on reducing or eliminating the inherent risks that are present in the operations, coupled with ongoing attention to human behaviour. The Lost Time Injury Frequency Rate decreased to below 0,10 for the first time and was recorded at 0,097 (2008: 0,11), the lowest rate amongst all companies assessed by NOSA. Further external recognition was achieved with the recognition by NOSA of the Maidstone sugar mill as the best manufacturing facility, both locally and internationally, that uses NOSA accreditation for safety, health and environmental systems. Tragically, a single onsite incident resulted in one fatality and two offsite incidents resulted in ten fatalities. At the Xinavane mill, nine security officers were fatally injured in a motor vehicle collision that took place on a public road near the sugar mill and an employee who suffered hot water burns onsite died from a subsequent infection. In Zimbabwe, another motor vehicle collision offsite claimed the life of an employee.

The provision of primary health care services continues to receive a high focus with particular emphasis on the health risks posed by HIV and AIDS, malaria and cholera to staff and the communities in the regions in which the company operates. Socio-economic development spend for the fifteen months ended March 2010, including the cost of company sponsored occupational and primary health care services, was in excess of R130 million.

Tongaat Hulett continues to be recognised for its achievements in the area of transformation. In Mozambique and Zimbabwe, further progress was made in expanding the contribution of the outgrowers and the surrounding communities in cane supply to the operations. In South Africa, Tongaat Hulett was ranked as the top food and beverage company in the annual Financial Mail empowerment survey and in the third BEE accreditation process achieved a score of 78,23 percent (2008: 70,38 percent) and was awarded Level Three Contributor status in terms of the broad based South African BEE scorecard.

TONGAAT HULETT’S COMPETITIVE POSITION IN A CHANGING WORLD OF AGRICULTURE

Review of Agricultural Commodity Markets

The volatility experienced in global agricultural commodity markets has been unprecedented with most markets reaching all time highs in 2008 and then facing significant declines as the sell off in commodities that arose from the global financial crisis took effect. The resumption of growth in world markets is expected to re-establish the fundamentals that supported the strong growth in demand in agricultural markets. These fundamentals include an underlying growth in food demand driven by an increase in the global population, income growth and changing dietary patterns in developing countries. This is coupled with an increase in the estimated number of undernourished people in the world to 960 million, requiring a further expansion in global food production. Low and stable prices for agricultural commodities that existed during the past two decades discouraged the necessary increases in production and resulted in a decrease in global stocks. These factors, coupled with the development of renewable energy and continuing market reforms, have resulted in the prices of agricultural commodities remaining above their longer term average despite recent reductions due to current global market conditions.

International maize prices have followed agricultural commodity markets and after rising to record levels during the first part of 2008 decreased to current levels as the impact of the global financial market crisis, record yields and the largest crop on record in the United States led to the stabilisation of inventories. Despite these declines, international maize prices remain above their long term average as an increasing proportion of maize production is diverted to ethanol production. The higher international prices, coupled with declines in input costs and productivity improvements in South Africa, resulted in South African maize prices that allowed farmers in the 2009 harvest season to cover input costs whilst local prices remained competitive in world terms. This supported improved margins in the production of starch-based products.

After years of worldwide surplus sugar production, demand has exceeded supply in four of the last six years. The growth in ethanol production in Brazil, the contraction and volatility in Indian production and the continued reform of the European Union (EU) have been the dominant supply side factors. Growth in consumption in the developing world and in particular, China and India’s increasing urbanisation and changing dietary needs of their populations are expected to support an annual growth in sugar consumption in excess of 3 million tons. The combination of these factors saw world sugar prices increasing to historic levels of 30 cents per pound in September 2009 before retracing to current levels of 14 to 16 US cents per pound.

Sugar Market Dynamics

The volatility in the sugar prices referred to above reflects the short term trends in the residual world raw sugar market. Nearly 80 percent of the global sugar production of approximately 160 million tons is consumed either in its country of origin behind some form of protective barrier or in certain export markets under agreements that give producers preferential access to these markets. Tongaat Hulett has a low exposure to the residual world market with less than 20 percent of its sugar production sold in this market.

Under the terms of the Everything But Arms (EBA) agreements for Least Developed Countries (LDC), which came into effect on 1 October 2009 and remain in effect until 2015, sugar production for Tongaat Hulett’s Mozambique and Zimbabwe operations has duty free and quota free access to the premium European markets at prices not less than the institutional reference price for raw sugar of €335,20 per ton. In Mozambique and Zimbabwe, sugar production is sold first in the growing domestic markets, which typically offer higher realisations than the European markets, with the balance of the production exported to the EU. Since October 2009, 76 000 tons of sugar have been sold to buyers in the EU at prices in excess of the institutional benchmarks. Domestic market consumption in Zimbabwe and Mozambique continues to grow in line with improved distribution infrastructure and economic performance.

In South Africa, Tongaat Hulett, with its Huletts® brand, remains the market leader in the direct refined market. The South African sugar industry is regulated by the Sugar Act, 1978 and the Sugar Industry Agreement, 2000. It produces, depending on climatic conditions, between 2,2 to 2,4 million tons of sugar per annum from 14 sugar mills. Sugar consumption within SADC continues to grow in line with population growth rates with South African/SACU market demand amounting to close to 2 million tons of sugar in the year ended March 2010. It is largely a refined white sugar market with 83 to 90 percent of the sugar sold in this form during the past two decades. An anomaly in this market is the continued flow of sugar imports from Swaziland despite the improved market access granted to Swaziland by the EU. Swaziland sales amount to more than 300 000 tons of sugar annually into the South African market, which currently has no access to the EU. Discussions between the South African and Swaziland industries, which could see Swaziland exiting all SACU markets and export to the EU have so far not been successful. The South African Department of Trade and Industry has undertaken to pursue this matter at an inter-governmental level.

Over time, the gap between the residual world market and domestic sugar markets is expected to close as the cost of producing sugar with new capital continues to increase and the diversion of sugar production to ethanol continues.

The need to develop new sources of sugar production is also likely because of a change in funding policy by the Brazilian government backed development bank, BNDES, which stopped financing greenfields sugar investments in Brazil in 2006, as Brazil’s share of world sugar trade rose to levels deemed commercially unsustainable. BNDES currently supports consolidation of sugar production and the aggressive expansion of fuel ethanol for the Brazilian market.

In India, increases in production that will probably occur over the medium to longer term are likely to be absorbed by the local market as India establishes an ethanol regime to meet climate change commitments and a more prosperous Indian population increases its consumption.

The scarcity of suitable land and water for agricultural use in developed markets, coupled with a declining rate of yield productivity improvements, will in the longer term, result in a tighter supply and demand situation in these regions. Sub-Saharan Africa, with less than ten percent of its existing available fresh water resources being utilised and a cropland potential substantially more than that of Brazil, is in a position to make more efficient use of these resources in order to increase agricultural production. These factors are expected to result in the improved viability of the agricultural sector in developing countries, such as Mozambique and Zimbabwe, as new sources of sugar production are required to be developed to support the underlying growth in demand.

Improving Shareholder Returns Through an Increase in Raw Sugar Production and Improved Agricultural Competitiveness

The estimated cost of investment in a greenfield sugar mill and its associated estates and infrastructure with the cane processing capacity to produce 200 000 tons of sugar is estimated to be in excess of R3,0 billion. In 2009, Tongaat Hulett’s results reflected sugar production of 1,0 million tons out of a total milling capacity of in excess of 1,9 million tons. In a world market where demand is increasing and the replacement cost of new milling capacity and its associated cane developments is high, Tongaat Hulett has the opportunity to enhance shareholder returns by increasing the utilisation of its existing milling assets. This will be achieved through a combination of initiatives that seek to improve yields and the cane to sugar recoveries and increase the area under cane, with a simultaneous reduction in unit costs of production. In addition to improving its existing capacity utilisation the company also has a number of options about where it is most appropriate to expand sugar production in order to leverage its existing investments in the region and beyond.

Initial plans aimed at achieving the incremental sugar production include an increase in the area under cane by 24 percent and an improvement in cane yields and the cane to sugar ratio by 37 percent and 7 percent respectively. The improvement in yields indicated is a crucial element in increasing the competitiveness of agriculture on the company’s own and the private grower estates. The issues affecting yields vary across the estates and are dependant on their location, whether the estates are rain fed or irrigated and farming practices. Various initiatives are underway that seek to improve farming practices and encourage reinvestment in replanting using the appropriate cane varieties. In order to increase the area under cane, a number of different options that include the expansion of own estates, the development of new or expanded private grower estates and the leasing of land for own estates are being considered. Initiatives to reduce the delivered cost of cane to the mills by improving harvesting and transportation modes and practices are being reviewed. The specific actions underway in each region are covered under the review of operations included in this report.

Renewable Energy and Low Carbon Energy Markets

Evidence of climate change because of increased levels of greenhouse gases such as carbon dioxide (CO2) is becoming more compelling. The recent Copenhagen Accord accepted that deep cuts in global emissions are required in order to ensure that the global temperature rise is kept to below two degrees Celsius. It is estimated that energy generation accounts for up to 60 percent of global CO2 emissions from human activities and the reduction of its impact on the environment remains a policy imperative for many national governments as they seek to reduce CO2

In South and North America and in the EU, existing investments in ethanol and biodiesel facilities, coupled with United States legislation, such as the Energy Policy Act of 2005 and the Energy Independence and Security Act of 2007 and similar legislation in the EU, are expected to sustain demand for biofuels in order to reduce their dependence on fossil fuel.

As part of the Copenhagen process South Africa made a commitment to achieve a saving of 34 percent in CO2 emissions by 2020 when benchmarked against normal growth projections. This commitment translates into far higher renewable energy targets than the current Department of Energy targets and is conditional upon the receipt of funding, transfer of technology and capacity building support by developed countries. Industrial energy, renewable energy, carbon reduction targets and biofuels policies are currently being reviewed by the South African government. Tongaat Hulett is actively pursuing opportunities to influence policy in order to ensure the sustainability of the industry. The impacts of renewable energy affect many government departments and ministries, increasing the complexity of the task of establishing an effective policy framework. In addition to the interactions in South Africa, interaction with selected SADC countries and the SADC Secretariat is being pursued in order to facilitate a SADC bio-energy and biofuels policy.

South Africa currently consumes 70 percent of the fuel in SADC and has limited agricultural potential to supply a significant portion of its petrol from ethanol. Many of the other SADC countries have excellent agricultural potential but limited markets. SADC combined has the market and agricultural potential to emulate the proven business model of ethanol to the fuel market. In Brazil, 60 percent of its petrol demand is currently supplied from ethanol. Even South Africa, with its limited water, low rainfall and established agriculture has the potential to provide 10 to 25 percent of its ethanol requirement. Every 10 percent of the current South African fuel market supplied by ethanol from cane is equivalent to a new South African sugar industry requiring 2,2 million tons of sugar per annum, creating 110 000 additional jobs and producing sufficient electricity to replace the supply from one third of a mega coal fired power station. The annual value of the potential carbon credit for electricity produced by such an expansion would amount to R2,4 billion under conditions where the credits were valued at €40 per ton of CO2. The future of a renewable low carbon energy regime supporting sustainable growth and developing the regional rural economy is possible for SADC by pooling the regional markets and agricultural potentials.

In South Africa, the National Electricity Regulator of South Africa (NERSA) published Renewable Feed-In Tariffs (REFIT) in 2009 for nine different technologies which ranged from R0,90 per kWh to R3,94 per kWh. A REFIT tariff applicable for electricity from bagasse could be published in 2010. Eskom’s long term adequacy plans require that 3 500 MW of electricity is supplied from cogeneration and renewable energy projects. In a medium electricity demand scenario, the reserve margin will not improve to adequate levels following the Eskom capacity build programme without the rollout of these energy projects. At this stage it is likely that the South African REFIT will only apply to South Africa and not to SADC.

Renewable energy in the Southern African sugar industry remains a key element for the growth and long term viability of millers and growers as it creates opportunities for increased realisations from bagasse, molasses and sugar cane juice. Tongaat Hulett’s sugar mills in Southern Africa, operating at full capacity, would have the potential to generate approximately 660MW of electricity using current technologies if they were to utilise all the bagasse and two thirds of the tops and trash from the cane supplied to the mills. This would have the environmental benefit of saving two million tons of coal annually and reduce CO2 emissions by 4,25 million tons in a season.

Tongaat Hulett continues to pursue opportunities for producing bio-ethanol from sugar and expanding the production of renewable electricity from cogeneration. Examples of these are the 10 000 hectare concession at Moamba as part of the further expansion plans at Xinavane and the Felixton cogeneration project. The primary focus of ethanol production at the Moamba operations would be for sale into South Africa and SADC states as part of South Africa’s and the SADC states’ emerging biofuels strategy as well as into the EU to take advantage of the duty free access for LDC and African, Caribbean and Pacific (ACP) countries. The detailed design and engineering for the expansion of cogeneration at Felixton has been completed and is dependent on the decision by NERSA in respect of the tariffs for electricity generation from bagasse.

Regulation Within the South African Sugar Industry

Sugar industries throughout the world continue to be influenced by national legislation in order to promote the growth and sustainability of the sugar industry, typically usingmechanisms which protect against dumped imports. Globally sugar industries are faced with rising costs of production, climate change, changes required by international trade agreements under the World Trade Organisation (WTO), the value of sugar cane as a source of renewable energy, and the emerging impact and value of sugar cane as an option for carbon abatement at a national level. Coupled with this, international trade is moving towards a regional alignment rather than the previous bilateral models. Consequently sugar industry frameworks, such as those in South Africa and SADC that were traditionally based on sugar and molasses in a national context need to be reviewed. Whilst the traditional products of sugar and molasses will remain dominant within any new regulatory framework, ethanol production and electricity generation will play an increasingly important role, particularly when regional trade in ethanol and electricity is considered.

In South Africa, the existing structures have discouraged growth and reinvestment in the industry. The structure and framework within the South African and Swaziland sugar industries will require significant change to meet the requirements of developing a sustainable regional market for sugar that captures the value of electricity and ethanol, whilst also ensuring that they remain competitive producers of sugar and molasses. Discussions within the South African sugar industry have begun to bring about the necessary changes to accommodate the new products and processes and to ensure the growth and development of the sugar industry. Tongaat Hulett is participating actively in developing the framework that will take sugar cane growers and processors forward over the next 15 to 20 years. One of the potential outcomes is that regional trade in sugar within SADC is likely to become a reality with the integration of markets subsequently extending to the largest market, SACU.

Creating Stakeholder Value for All from Agricultural Land Conversion

Globally, prime coastal land close to major cities has shown real appreciation that exceeds the time value of money over the long term. eThekwini continues to expand because of population increases, ongoing urbanisation and recovering economic growth.

During 2008 and 2009, the worldwide liquidity crisis and extreme volatility in markets led to uncertain and depressed property market conditions. The opening of the new King Shaka International Airport at La Mercy, with its ability to attract direct international flights, the development of the surrounding trade port and the expansion of the existing port will, over time, generate new investment in the region. As the region evolves, demand for properties for tourist, logistics, manufacturing, services and residential purposes is likely to increase.

Current political and social dynamics are resulting in an increased demand for land for low income housing, creating both the opportunity and socio-economic urgency to establish communities with affordable, quality housing, health care, educational and social facilities. During the period, the company continued to engage and collaborate with the eThekwini municipality in developing the planning processes which set the framework for the growth and direction of development and new investment, as well as provide guidance from a land use and intensity perspective. This was most evident in relation to the developments at Cornubia, where planning and environmental applications have been made by a joint project team that meets on a weekly basis.

Tongaat Hulett’s landholdings include land suitable for the city’s expansion. Its landholdings consist of 6 442 hectares in the prime developable coastal and tourism areas north of Durban, a further 2 047 hectares to the west of the city and 5 374 hectares located in the eThekwini growth corridor north of the city.

In the current property cycle, few hectares have been or are expected to be converted in the high value, prime locations on the coastline and to the west of eThekwini and the focus remains on increasing stakeholder value through planning processes, rezoning and environmental approvals and infrastructure investment in cooperation with the appropriate spheres of government. This will ensure that there is adequate stock of development land available for conversion when market conditions are appropriate.

FINANCIAL RESULTS FOR THE 15 MONTHS ENDED MARCH 2010

Revenue increased by 18 percent to R11,1 billion for the 15 month period ended March 2010 and profit from operations grew by 28 percent to R1,691 billion, compared to the corresponding 15 month prior period. Headline earnings improved by 37 percent to R858 million (prior period: R626 million).

The financial year end has changed to the end of March, which corresponds with the sugar season in all countries in which Tongaat Hulett operates. The current financial results are thus for the 15 months to 31 March 2010 and include the revenue of a single sugar milling season and the increased value of the growing crop. The costs are for a 15 month period, including those costs incurred from January to March in the off-crop period that are required to be expensed in the income statement.

Profit from the starch operations for the 15 months was R301 million, compared to R290 million in the prior period. Starch and glucose sales volumes in the local market declined by 5 percent over this period, with the rate of decline slowing in the first quarter of 2010. Lower demand was experienced in the alcoholic beverage, paper, coffee creamer and confectionary sectors, with the contraction in consumer spending. The negative effect of the lower demand was offset by improved starch and glucose margins. A second consecutive year of favourable agricultural conditions in South Africa yielded a large maize crop in 2009 of 12,9 million tons (previous crop: 12,7 million tons) and resulted in local maize prices trading closer to world prices for most of the year. Co-product revenues decreased as a result of lower prices for edible oils and animal feeds.

Operating profit from land conversion and development for the 15 months to March 2010 amounted to R187 million (prior period: R256 million) with a further R52 million in capital profits (prior period: R22 million) being realised. During this period, 169 developable hectares (280 gross hectares) were sold comprising 159 hectares in the eThekwini growth corridor, including new airport related activities, and 10 hectares in the prime coastal corridor.

The South African sugar milling, refining and agriculture operations contributed R158 million to profit for the 15 months ended March 2010 (prior period: R95 million), with higher local and export sales realisations. Sugar production decreased to 564 000 tons compared to the 644 000 tons produced in the previous season. Almost all of Tongaat Hulett’s sugar production was sold in the local market under the Huletts brand in 2009/10. In terms of the South African sugar industry legislated regulations, only 65 percent of the sales were deemed to be local and 35 percent were recognised and valued as exports. Raw sugar export volumes from South Africa were sold at an effective world sugar price of 15,4 US c/lb (prior year: 12,1 US c/lb) at an average exchange rate of R8,20/US$ (prior year: R8,05/US$).

The downstream sugar value added activities contributed R226 million to profit (prior period: R230 million). This includes Voermol® animal feeds, South African refined exports, regional marketing, sales, packing and distribution activities.

In Swaziland, Tambankulu Estates produced a raw sugar equivalent of 54 000 tons (previous season: 56 000 tons). Operating profit for the 15 months, including the value of the cane growth in the period of January to March 2010, was R63 million, compared to R56 million in the prior period.

Sugar production in Mozambique increased to 134 000 tons from 108 000 tons in the previous season. The start-up problems that limited sugar production in 2009/10 at the expanded and modernised Xinavane mill have now been resolved, including replacing the diffuser chain and modifying conveyer systems. This resulted in a large portion of the crop on the substantially expanded cane growing estates being carried over, for harvesting at the start of the 2010/11 season. Production of sugar at Xinavane was 89 000 tons (previous season: 63 000 tons). Mafambisse’s sugar production of 45 000 tons (previous season: 45 000 tons) was adversely affected by a number of factors, including the harvesting of young cane in the newly established cane areas and overcoming irrigation bottlenecks. The Mozambique operation’s raw sugar export volumes to the European Union totalled 49 000 tons (prior: 39 000 tons) and sales to the domestic market increased to 85 000 tons (prior: 69 000 tons). The currency gains of R122 million realised in 2008, when financial structures were finalised, were not repeated in 2009/10. The Mozambique profit from operations amounted to R192 million (prior period: R301 million).

The profit from sugar operations in Zimbabwe was R576 million in the 15 months to March 2010, as relevant economic fundamentals were reintroduced into the local economy and the business. Sales to the domestic market of 188 000 tons were undertaken in US dollars at levels in line with regional pricing and 146 000 tons were exported to the European Union. Sugar production in Zimbabwe amounted to 259 000 tons (previous season: 298 000 tons). The situation that prevailed in Zimbabwe in 2008 had a negative impact on the 2009 harvest and sugar production levels.

The recovery of the Zimbabwe sugar operations commenced in 2009, coinciding with the US dollarisation of the Zimbabwe economy and the return to more normal economic fundamentals relevant to the sugar business, including the restoration of domestic sales prices to regional levels. As reported in the interim results, the Zimbabwe operations are consolidated in Tongaat Hulett’s financial results from the beginning of 2009. The accounting treatment, in terms of International Financial Reporting Standards, on the commencement of consolidation of these operations gave rise to a balance sheet take-on gain of R1,969 billion, which is recognised in the income statement. This gain is excluded from the profit from operations and excluded from headline earnings.

The centrally accounted and consolidation items include a R82 million gain (prior period: R86 million) on the recognition of an unconditional entitlement in 2009 to an employer surplus account allocation in the Tongaat Hulett pension fund.

The tax charge in the income statement includes the benefit of a release from the deferred tax provision following the reduction of the Zimbabwe tax rate from 30 percent to 25 percent at the end of 2009 and the advantage of an attractive Mozambique tax rate for agricultural operations.

Finance costs for the 15 months to March 2010 increased to R452 million from R367 million in the equivalent prior period, commensurate with the borrowings in the business.

Cash inflow from operations was R1,955 billion for the 15 months to March 2010. Tongaat Hulett’s net debt at the end of March 2010 was R3,040 billion (compared to R3,370 billion at December 2009 and R2,356 billion at December 2008) with significant capital expenditure, mainly on the Mozambique expansion, cash absorption in the establishment of the expanded cane crops and replanting of sugar cane in Zimbabwe.

The Board has declared a final distribution, as a scrip distribution with a cash dividend alternative of 175 cents per share, bringing the total distribution for the full period to 275 cents per share. There is a separate detailed announcement on the scrip distribution with the related circular posted to shareholders.

REVIEW OF TONGAAT HULETT’S OPERATIONS

Tongaat Hulett has the advantage of owning a compelling mix of agri-processing assets in Southern Africa with acc ess to attractive markets. Its expansion path favours utilising a combination of its own and private grower estates in agriculture, and large scale agri-processing operations in selected countries. Ensuring the viability and success of private growers for whom access to the well located sugar mill is an essential requirement to invest in cane production remains a critical success factor for the sugar mill. The provision of support to private growers includes the supply of the correct seed cane varieties, extension services for training and development to improve farming practices and the establishment of the necessary logistics and cane harvesting service to ensure that the cane is deli vered to the sugar mill. Tongaat Hulett’s core competencies within the business include understanding and establishing social, political and community support in Africa and the associated land and water management requirements. Through its South African sugar and starch and glucose operations, it produces almost half of the refined carbohydrates manufactured in South Africa. In starch, one of nature’s most versatile raw materials, and in sugar, arguably nature’s most efficient source of carbohydrate, Tongaat Hulett has the platform for a variety of downstream products. Product development within the organisation follows an integrated approach between the sugar and starch operations. The liquid fructose plant commissioned in 2008 has successfully gained market share by displacing imports and by the end of 2009, sales were constrained by production capacity and a feasibility study for the second phase of the project was underway. Similar opportunities for product expansion exist in the starch operation and the development of an extended range of modified starch production is currently being evaluated. Tongaat Hulett’s four significant operations in Mozambique and Zimbabwe are located in agricultural areas that represent some of the lowest cost sugar production regions in the world.

The interrelationships between crops, such as soya and other edible oils, maize, cassava, wheat and sugar cane are increasing as farmers and agri-processors are confronted with choices as to which crops to farm and process, based on their relative profitability, initial input costs and financing requirements. Tongaat Hulett, with its portfolio of agri-processing assets, is well positioned in this world of increasing demand for agricultural products.

SOUTH AFRICAN SUGAR OPERATIONS

SA Sugar Crop, Agriculture, Cane Supply and Milling Capacity Utilisation Initiatives

The sugar mills situated on the north coast of KwaZulu-Natal continued to experience a shortage of cane supply. Grower viability in the predominantly rain-fed coastal region, uncertainty around land tenure created by the delayed restitution process and drier weather conditions discouraged grower reinvestment. The reduced reinvestment is particularly evident in delayed replant programmes combined with reductions in key inputs, such as fertiliser, and has contributed to declining cane yields and cane supply that have been exacerbated by the introduction of grower ownership in two competitor north coast mills which are competing for the limited cane supply. In 2009 the area under cane decreased by 10 454 hectares to 130 594 hectares and this coupled with the reduction in yields limited sugar production in 2009 to 564 000 tons (2008: 644 000 tons).

Sugar cane production per hectare of cane has declined by 30 percent from average levels of 64 tons per hectare achieved in 2000 because of the factors outlined above. In order to increase the utilisation of the existing capacity at its South African cane milling operations, various land management and cane supply initiatives to increase the area of land under cane and improve yields have been identified for implementation.

The dominant features of achieving greater yields per hectare lie in encouraging growers to reinvest in replanting and improving farming practices. Interventions designed to encourage and enable growers to replant and apply the correct farming practices are currently underway with the aim of returning yields to the levels previously achieved in a good rainfall year. These processes are supported by the expansion of Tongaat Hulett’s cane extension services and the establishment of cane on third party land that is fallow or being utilised for alternate crops. Initiatives to increase cane supply by acquiring land that is currently not supplying the mills continue to be pursued. These initiatives also support property development and enhance the value of Tongaat Hulett’s existing land holdings. During the planting season from September 2009 to January 2010, new areas under cane totalling 4 513 hectares were established through a combination of expanded or new small scale grower, commercial grower and Tongaat Hulett leased land estates. Further expansions of the area under cane amounting to 8 084 hectares are planned for the 2010/11 planting period. In addition to these new areas under cane the company has been successful in achieving a net increase in the supply of cane from third parties of 2 013 hectares during the current season and has seen a reduction in the area under cane amounting to 200 hectares in the area surrounding the airport. The combination of these initiatives should result in the cane harvested supplying the South African mills expanding from 111 005 hectares in 2009 to a targeted 123 715 hectares in 2012.

As part of the overall land management process, Tongaat Hulett is assisting in the land claims processes within its cane catchment area in a positive and constructive manner that is designed to ensure cane supply to its mills is sustained. The post settlement model entails working with the claimant communities in order to assist them with business management and the development of successful farming practices, both during the transitional period prior to the settling of the claim and once the claimant community has taken ownership of the land.

Operational Performance – Milling and Refining

Tongaat Hulett’s sugar technology leadership was confirmed during the year with milling performance continuing to exceed industry benchmarks measured in terms of crystal sugar recovery. Further improvements in efficiencies and capacity utilisation at the refinery resulted in refined sugar production increasing to 611 000 tons in 2009 (2008: 549 000 tons). These improvements resulted in cash operating costs for the refinery of US$38 to US$45 per ton. Refining margins improved during the period as the refined white sugar premium increased. The international refining margin has typically traded in a range of US$70 to US$80 per ton.

Domestic Market

Tongaat Hulett continues to optimise the value of the Huletts® brand as the leading sugar brand in South Africa. The brand remains the cornerstone of Tongaat Hulett’s market positioning and offers a total sweetener solution including a range of high intensity sweeteners and liquid fructose.

International Markets

The two small sugar crops in 2008 and 2009, have resulted in lower export sales from South Africa. These sales were achieved at an effective world sugar price of 15,4 US cents per pound (2008: 12,1 US cents per pound) and an average exchange rate of R8,20/US$ (2008: R8,05/US$).

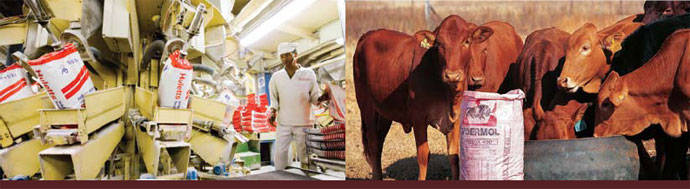

Voermol

Having pioneered the production of bagasse and molasses-based animal feeds under the Voermol® brand, this operation continues to be a leader with its range of energy and supplementary feeds, amongst others, as the cornerstone of its offerings to the livestock farming community. This operation is integral to the strategy of optimising value from molasses and bagasse from the sugar mills and showed an increased contribution to earnings.

MOZAMBIQUE SUGAR OPERATIONS

Tongaat Hulett’s sugar operations in Mozambique consist of the Xinavane and Mafambisse sugar mills and surrounding estates. The 2009/10 year was a significant milestone in the development of these operations with cane growing activities being undertaken on significantly expanded sugar cane estates and a corresponding increase in milling capacity to crush the increased harvests in the years ahead.

Agriculture and Milling Capacity Expansions, Mozambique Sugar Crop

During 2009/10 the cultivated area of sugar cane, for delivery to the Xinavane and Mafambisse mills, almost doubled to 24 638 hectares (2008: 12 877 hectares) and comprised 21 410 hectares of company-owned estates and 3 498 hectares farmed by private growers. This represents 90 percent of the area required in order to meet the newly installed milling capacity with the balance of 2 738 hectares being planted in 2010. The annual cane harvest, including that of private growers, is expected to rise to over 2,6 million tons.

The expansion of the Xinavane sugar mill was completed in 2009/10 increasing its sugar production capacity to in excess of 208 000 tons in a 32 week crushing season. Together with the existing 92 000 tons of capacity at the Mafambisse sugar mill, the Mozambique operations have the installed milling capacity to produce in excess of 300 000 tons per annum.

Sugar production in 2009 in Mozambique increased to 134 000 tons from 108 000 tons in 2008. The start-up problems that limited sugar production at the expanded and modernised Xinavane mill have been resolved, including replacing the diffuser chain and modifying the cane and bagasse conveyer systems. The delayed start-up resulted in a large portion of the crop on the expanded cane growing estates being carried over, for harvesting at the start of the 2010/11 season. Production of sugar at Xinavane in the last season was 89 000 tons (2008: 63 000 tons). Mafambisse’s sugar production of 45 000 tons (2008: 45 000 tons) was adversely affected by a number of factors, including the harvesting of young cane in the newly established cane areas and irrigation bottlenecks.

Following the expansion and project activities of the past period, the current focus of attention in Mozambique is on improving operational excellence. Plans are in place to improve cane yields and sugar recoveries and reduce the inefficiencies in the cane loading and transportation process in order to increase sugar production over the next two seasons from the 134 000 tons produced in 2009/10 to the installed milling capacity of over 300 000 tons per annum.

Sugar Markets

The Mozambique operation’s raw sugar export volumes to the EU totalled 49 000 tons (2008: 39 000 tons) and sales to the domestic market increased to 85 000 tons (2008: 69 000 tons). Sales to the EU were constrained by improved local demand in Mozambique and Zimbabwe and by better returns from sales to other markets such as the United States (US) where prices reflected the dramatic increases seen in the international market. Tongaat Hulett continues to see strong demand for its sugar from premium buyers in the EU.

SWAZILAND SUGAR CANE OPERATION

The Tambankulu sugar cane estate in Swaziland has consistently achieved excellent sucrose yields due to the good soils and growing conditions in the region. The estate of is situated in the north east of Swaziland and comprises of 3 767 hectares of fully irrigated cane estates. The company delivers its cane to the nearby Simunye and Mhlume sugar mills. The estate harvested 432 577 tons of sugar cane in 2009 (2008: 458 592 tons) equivalent to 54 000 tons of raw sugar (2008: 56 000 tons).

ZIMBABWE SUGAR OPERATIONS

Tongaat Hulett’s sugar operations in Zimbabwe comprise the wholly owned Triangle Sugar operation and its 50,3 percent holding in Hippo Valley Estates.

Agriculture and Milling Capacity, Zimbabwe Sugar Crop

The Zimbabwe operations farm 29 000 hectares with a demonstrated potential to produce in excess of 3,4 million tons of sugar cane annually. Private growers have been allocated a further 15 800 hectares all of which were previously under cane and which have the demonstrated potential to produce in excess of 1,5 million tons of cane annually.

The Triangle and Hippo Valley Estates sugar mills have a combined installed milling capacity to crush in excess of 4,8 million tons of cane annually and produce over 600 000 tons of sugar. Refining capacity is 150 000 tons per annum.

Sugar production in Zimbabwe in 2009 amounted to 259 000 tons (2008: 298 000 tons). The situation that prevailed in Zimbabwe in 2008 had a negative impact on the 2009 harvest and sugar production levels.

Since February 2009, sales to the domestic market have been conducted in US dollars at prices in line with regional prices and amounted to 188 000 tons as demand in the domestic economy continued to improve. A further 146 000 tons of sugar production was exported to the EU.

The fermentation and distillation capacity to produce either alcohol or fuel grade ethanol is rated at 27 million litres per annum and was re-commissioned during January 2010. Clarity on the Zimbabwean blending policy is still required to facilitate sales of fuel grade ethanol in the local market. In 2010/11 the plant is expected to produce 23,4 million litres of potable and industrial grade ethanol with 75 percent being exported to South Africa and the balance sold domestically and regionally.

Integration of Triangle and Hippo Valley Estates

The pace of integration of Triangle with Hippo Valley Estates and the realisation of rationalisation and synergistic benefits in order to improve cost competitiveness has increased as the business environment normalises. Initiatives include the alignment of policies, sugar marketing and branding, rationalisation of strategic stockholdings, integration of medical schemes and the sharing of skills and resources through joint management services. Procurement has a key role to play in re-establishing the Zimbabwe operations as a low cost producer by international standards and is an area that is receiving particular emphasis as the economy adjusts from a hyper-inflationary Zimbabwe dollar environment to a more predictable US dollar denominated economy.

Rehabilitation of Existing Capacities

The improved macroeconomic conditions that have prevailed in Zimbabwe since the beginning of 2009 are facilitating the escalation of actions and programmes focused on restoring cane and sugar production to 4,8 million and 600 000 tons, respectively.

These plans include upgrading the two sugar mills in order to restore reliability and sugar recoveries, cane yield improvement programmes on the company farmed and private grower estates and plans to restore cane production over the next three to four years on 11 100 hectares of private grower land.

Integral to the plans to restore private grower cane production is the continued access to the EU’s Adaption Funding made available to qualifying ACP countries following the reform of the EU’s sugar regime and the resultant decrease in the value of the EU as a preferentially priced market. In the case of Zimbabwe, €45 million has been allocated, most of which will be channelled through the Canelands Trust that has been set up by the company, with oversight provided by the EU and the government of Zimbabwe.

The first two tranches of €2,7 million and €6,5 million have been made available with the first tranche being used to establish the administrative capability of the project. The focus of the second tranche is the re-establishment in 2010/11 of 1 200 hectares of private grower land in the Chipwa and Mpapa regions.

A third tranche of €13 million that will fund the re-establishment of 7 000 hectares has been provided for by the EU and is conditional upon progress being made on Zimbabwe’s land audit, as provided for in the Global Political Agreement signed in 2008. The focus of attention in any land audit will be on land administration, land tenure, compensation and dispute resolution.

The improved macroeconomic environment and the fact that realisations for sugar sold on the domestic market in US dollars are at levels in line with regional prices has improved the viability of cane farming in Zimbabwe to the levels commensurate with those expected from high yielding irrigated cane land.

Triangle and Hippo Valley are escalating the provision of extension services and support programmes to all qualifying private growers including extensive technical training and the sourcing of key inputs. The combined effects of the rehabilitation activities outlined above are expected to result in a 20 percent increase in cane crushed and a 27 percent increase in sugar production to in excess of 330 000 tons in 2010/11.

STARCH AND GLUCOSE

Maize Procurement

The slowdown in the world economy resulted in decreases in the prices of many agricultural commodities, including maize. Despite this, prices, remain significantly above the long term average prices as worldwide demand for food increases and an increasing proportion of food crops are diverted to renewable energy resulting in lower global food commodity stocks. The higher international prices encouraged increases in plantings in South Africa and this, combined with good weather conditions, resulted in a crop of 12,9 million tons being harvested in 2009 (2008: 12,7 million tons). This has resulted in local prices remaining closer to export parity, thereby supporting Tongaat Hulett’s competitive position. The improved profitability of local maize compared to competing crops and in relation to prior periods, resulted in an increase in the planting area for the 2009/10 production season to 2,76 million hectares (2008/09: 2,56 million hectares). The increased area, combined with excellent rains, is expected to yield a crop in excess of 13 million tons, the largest for nearly three decades, and ensure that local maize prices remain competitive with international prices.

International prices, after peaking at a price of US$295 per ton in July 2008, have declined to levels around US$150 per ton because of the impact of the world economic situation and falling oil prices. At these levels, prices remain above the long term average Chicago Board of Trade (CBOT) price of US$80 to US$100 per ton. Local producers have been cushioned from this decline by the reduction in input costs and improvements in yields and local prices continue to trade at levels of US$5 to US$10 above the CBOT price.

Tongaat Hulett continues to secure its physical maize requirements of non-genetically modified maize through a combination of direct contracting with farmers and contracting for delivery with selected grain traders. The physical supply for the balance of the season to June 2010 and the requirements for the period June 2010 to May 2011 have been contracted.

The pricing of maize continues to be delinked from the physical supply utilising two established methods, namely toll manufacturing arrangements with selected customers where the final product price reflects the maize input costs, and the back-to-back contracting approach in which the maize is priced at the time the final product price is agreed with a customer. These approaches effectively eliminate the risk of profit volatility that could arise from valuation adjustments on maize. The back-to-back method does not eliminate the profit volatility which arises due to the relative prices of South African maize compared to the world prices.

A third pricing mechanism, which secures the local price of maize at a level relative to the international price, was introduced in 2008 and continues to be applied. This mechanism allows Tongaat Hulett to take advantage of periods when the South African maize price is at levels that are competitive with the international price of maize. This is achieved by contracting for a fixed quantity of maize at a local price that will maintain a constant premium or discount in US dollars to the CBOT price.

Utilisation of a combination of the above three methods has resulted in the maize price on approximately 67 percent of the 2010/11 financial period’s local maize requirements being hedged at levels close to the international price of maize at March 2010.

Local Market

Domestic volumes for starch and glucose for the fifteen month period declined by 5 percent as the effects of the global recession resulted in decreases in demand, particularly in the papermaking and corrugating sectors.

International starch and glucose prices, although declining because of the combined effects of the global recession on demand for products and lower commodity prices, did not decline at the same rate as prices in agricultural commodity markets. This allowed for the maintenance and, in the case of some products, improvement in margins. A similar pattern was experienced in the local market, although the improvement in margins was less pronounced due to the impact of higher electricity prices during the period.

New product development for value added starches for both the local and domestic markets continued during 2009/10, with notable success achieved in growing sales of starch-based adhesives to 1 458 tons.

A feasibility study to manufacture an extended range of modified food starches for local and international markets is underway and should be completed by mid 2010. The market potential identified equates to approximately 20 000 tons per annum for the local and export markets. In order to develop local and export markets, a toll manufacturing arrangement has been established with producers in Thailand. Investigations into enhanced animal feed formulations and the market development of the super-absorbent hydropolymer, Zeba® continued during the period.

Export Markets

Export volumes increased by 19 percent to 34 821 tons, facilitated by the South African maize price tracking close to the international maize price. The trading operation established in Australia, continues to develop its markets although growth during the period was affected by lower demand from the mining industry.

Cost Management, Efficiencies and Capacity Utilisation

Various initiatives to reduce costs and improve efficiencies continued during the period and saw improvements in the usage of utilities at all operations. Reductions in the protein available for extraction in maize hampered the projects underway to improve protein recovery.

The successful trials of the initial 20 000 ton bunker silo facility at the Kliprivier mill led to the expansion of this facility to 60 000 tons along with the establishment of an additional facility of 40 000 tons at the Meyerton mill. These silos assist in reducing storage and handling costs and are one of a number of initiatives being explored in order to improve grain handling at the operations. The utilisation of silo bags at various locations continued and was effective in reducing the overall costs of storage.

Trends in International Starch and Glucose Markets

Chinese maize starch costs have converged with cassava starch prices in Thailand. This was due to the effects of the drought in China and its impact on the Chinese maize crop and the impact of the limited availability of cassava root in Thailand on cassava starch prices. The cassava root shortage has been created due to farmers having to plant other crops because of an outbreak of disease in the cassava crop. In the US, sales of High Fructose Corn Syrup (HFCS) to soft drink manufacturers remain under pressure as the health debate surrounding "hollow calories" continues. The decrease in HFCS sales combined with spare capacity in the US wet milling industry has resulted in US producers of starch and glucose looking to re-enter export markets. Glucose and starch prices in China and Thailand are expected to remain firm in the short term supported by the high economic growth rates and maize and cassava prices.

LAND MANAGEMENT AND DEVELOPMENT

Land Management

Tongaat Hulett’s operational land footprint within the Southern African Development Community (SADC) region amounts to approximately 560 000 hectares. This footprint consists of 267 160 hectares of land that it owns or controls, a further 137 204 hectares of private grower land supplying cane to the four South African sugar mills, 4 700 hectares to the two Zimbabwe mills and 2 431 hectares to the two Mozambique mills. Approximately 150 000 hectares of private maize farmland supplies the four starch operations. In South Africa, 13 863 gross hectares out of a total of 22 771 hectares of company owned land has been identified as having a high potential for conversion to other uses when conditions are appropriate.

The organisation employs land management strategies that support the development and growth of sustainable agriculture in the region in order to maintain and increase the supply of cane and maize to Tongaat Hulett’s mills. A key strategy in this regard has been the proactive engagement of the company in the process of land reform. Its participation in this process seeks to support land redistribution and restitution in a positive and constructive manner that promotes agricultural and rural development and creates stakeholder value through land conversion activities. Its combination of agriculture, agri-processing and property development operations provides many options for satisfactorily dealing with land claim issues. Tongaat Hulett is able to prove ownership for all developable land dating back to before 1913.

Ongoing interaction between the various operations continues in order to identify opportunities within Southern Africa that are common to the sugar, starch and developments operations.

Creating Value for All from Agricultural Land Conversion

Worldwide, population growth, urbanisation, expanding middle classes, food scarcity and environmental concerns are increasing the competition for and underlying scarcity and value of agricultural and urban land. Urban areas are increasingly competing with each other for investment, while the need for the sustainable development of rural areas is an increasing priority. Although the cycles of property markets and the timing thereof are difficult to predict, Tongaat Hulett has, over a number of years, developed the ability to optimise stakeholder value creation for all from its landholdings, while minimising risk. A key factor in the success of Tongaat Hulett’s conversion of some 2 200 hectares of land over the past 15 years has been the fact that each development, whilst being commercially viable in its own right, has been able to increase the value of the remaining land assets.

As a major role player in KwaZulu-Natal, both as an employer and as a proactive and capable participant in the process of converting land from agricultural to other value enhancing uses, Tongaat Hulett’s land conversion activities have led to successful partnerships with various spheres of government, communities, suppliers and end users. These partnerships have improved interaction with local and provincial authorities and communities and allow for input into planning activities which set the framework for the growth and direction of development and new investment, as well as provide guidance from a land use and intensity perspective. A cooperation and alignment agreement was concluded in 2008 between Tongaat Hulett and eThekwini Municipality in respect of integrated human settlements generally and the Cornubia development specifically. Similarly, a joint planning initiative with the Dube Trade Port, a provincial government entity, for the region surrounding the King Shaka International Airport has been in operation since 2008.

The broad spectrum and location of Tongaat Hulett’s land holdings provides for a variety of development and land conversion models to be established. These range from the sale of land in bulk, serviced and unserviced, semi-bulk land sales, land exchange agreements, joint venture and partnership developments through to the traditional sale of smaller parcels of land from within a Tongaat Hulett development. The options, which require different levels of capital and infrastructure commitment, are evaluated before commencing each development or development phase.

Market Review and Operating Environment

Conditions for the conversion and sale of agricultural land remained depressed throughout 2009/10 with some recovery in demand experienced in residential markets towards the end of the period. Despite the reduction in prime interest rates from 15,5 percent in December 2008 to 10,0 percent in March 2010, banks remained reluctant to finance developments on undeveloped land and continue to apply stringent lending criteria and loan conditions. The recovery in demand is expected to continue at modest rates in the short term.

eThekwini Municipality continues to experience increasing urbanisation combined with an existing and growing demand for housing, social facilities and work opportunities. Extensive government investment in infrastructure has occurred in the region to the north of eThekwini, most notably the new King Shaka International Airport and its associated services infrastructure. The city’s growth is constrained by topography and its primary development opportunities lie to the north and west of the city. The pace of development will likely remain restricted because of ongoing constraints imposed by limitations in key elements of bulk infrastructure.

Tongaat Hulett, with approximately 9 581 gross hectares (5 780 developable hectares) located in the regions to the north and west of the city, is uniquely positioned to collaborate with government in the conversion of land for new housing and employment opportunities and the associated social infrastructure. Currently there are 450 gross hectares (264 developable hectares) of land with full development rights, while env ironmental and/or land use zoning applications are currently underway covering some 2 360 gross hectares (1 470 developable hectares) north of Durban, with processes for a further 761 gross hectares (479 developable hectares) scheduled to be launched during the 2010/11 financial year.

Through its partnerships with government and the opportunities that the eThekwini growth corridor provides, Tongaat Hulett concluded sales during the period of 159 developable hectares of land in the eThekwini growth corridor, including new airport related activities, while 10 hectares were sold in the prime coastal corridor. Tongaat Hulett is continuing to engage proactively with all spheres of government in pursuit of appropriate mechanisms to facilitate the acceleration of the conversion of agricultural land to urban uses. This will enable the region to maximise its competitiveness and ensure that it capitalises on the benefits that the new international air platform provides through improved accessibility to the world, increased tourism, enhanced port and airport linkages and synergies and the potential to compete for a position as a global destination and gateway into Africa.

CONCLUSION

Outlook

Tongaat Hulett’s land and property development activity is currently focused on opportunities in the growth corridor north of Durban, including those related to the new international air platform.

The South African maize harvest in 2010 is projected to be above 13 million tons, the largest crop in 29 years, which should maintain local maize prices close to world prices and contribute to the competitiveness of the starch operation.

The world sugar price, after rising substantially, has recently declined sharply to a level similar to the average earned on exports from South Africa in 2009/10. These exports currently constitute some 20 percent of Tongaat Hulett’s total sugar sales and this percentage will reduce as the Zimbabwe and Mozambique production increases. Movements in the Rand, US dollar and Euro exchange rates have a direct impact on export proceeds and the conversion of earnings into Rands by the operations outside South Africa.

The business is driving to increase sugar production from the 957 000 tons milled in the 2009/10 season to the installed sugar milling capacity of 1,9 million tons per annum, with a simultaneous reduction in the unit cost of production. Sugar production in the 2010/11 season is expected to be 20 percent to 25 percent above the previous season. Plans are in place to increase sugar production over the next two seasons in Mozambique from the 134 000 tons in 2009/10 to the newly installed milling capacity of 300 000 tons per annum, with the cane supply already well established. A recovery programme is currently underway in Zimbabwe, focused on the two sugar factories, improving cane yields and re-establishing private grower cane lands, so as to restore sugar production to the existing installed capacity of 600 000 tons per annum. In South Africa, the rainfall in the cane growing months has been below average for the 2010/11 season, which will affect the sugar operations. The focus in South Africa is on working with commercial and small scale growers on increasing hectares under cane, areas to be replanted and farming practices to improve yields, leading to higher milling capacity utilisation.

Tongaat Hulett remains well positioned to benefit from the medium to longer term global fundamentals of increasing demand for agricultural products, food, renewable energy and land usage.

Acknowledgments

I wish to pay tribute to the more than 35 000 employees of Tongaat Hulett and to thank them for their continuing dedication and commitment. In particular, it is encouraging to note the positive effects of changes taking place in Zimbabwe on the lives of our employees in this region. Working together, we have established a competitive platform that will stand us in good stead into the future.

In 2009, the board was delighted to welcome JB Magwaza as Chairman of Tongaat Hulett with effect from the Annual General Meeting held on 29 April 2009. JB’s relationship with the company spans 34 years, having joined Tongaat Hulett in 1975. He was appointed as an Executive Director in 1994 and served in a non-executive capacity since 2003. His vast experience in the business community, sound understanding of the business and his insights into the socio-political dynamics of the region will stand the company in good stead. We look forward to the positive impact that his advice and guidance will have on the company’s continued growth.

Rachel Kupara and Adriano Maleiane, who are based in Harare and Maputo respectively, were appointed as nonexecutive directors to our board. They bring an important regional insight and perspective to the board, in light of the increasing significance of the organisation’s operations outside South Africa. We further extend our appreciation to Hixonia Nyasulu, who has communicated her intention to resign from the board. We thank her for her dedicated service to Tongaat Hulett. We also welcome, as a non-executive director, Thandeka Mgoduso who will provide continuity in respect of Tongaat Hulett’s BEE equity initiative.

The support and guidance that we have received from the board is highly valued. Tongaat Hulett has benefited from their wise counsel and experience over a number of years.

Peter Staude

CHIEF EXECUTIVE OFFICER

Amanzimnyama

Tongaat, KwaZulu-Natal

26 May 2010