Sustainability

INTRODUCTION

This sustainability section is presented according to the capitals described in the International Integrated Reporting Council (IIRC) Integrated Reporting <IR> Framework, while financial capital has been covered in the relevant sections of this integrated annual report.

| VALUE CREATION

CAPITAL |

TONGAAT HULETT’S SUSTAINABILITY DRIVERS |

|||

SOCIAL AND

|

Stakeholder engagement Socio-economic development Creating sustainable communities Developing indigenous farmers Food security Supply chain Preferential procurement Safety, Health and Environment (SHE) Food safety Health |

|||

| NATURAL CAPITAL |

Environmental stewardship Climate change Carbon management Energy Air quality Biodiversity and land management Water resource management Effluent Waste management Environmental compliance |

|||

| HUMAN CAPITAL |

Employee base Employee development Employee diversity Industrial relations |

|||

MANUFACTURED CAPITAL |

Promoting sustainable agriculture Product responsibility |

|||

INTELLECTUAL CAPITAL |

Protection of intellectual property |

PERFORMANCE OVERVIEW

- Achieved a Lost Time Injury Frequency Rate (LTIFR) of 0,087 per 200 000 hours worked

- Xinavane agriculture operations completed a milestone achievement of 27,7 million Lost Time Injury (LTI)-free hours during the year

- Triangle agriculture operations registered 20,1 million LTI-free hours

- The Developments operation achieved ten years without experiencing an LTI. The last LTI was on 23 April 2004

- Sadly one fatality occurred during the period

- Achieved nine percent reduction in greenhouse gas emissions against a target of five percent per annum

- Industry-leading HIV/AIDS and Anti-retroviral Treatment (ART) programs across employee complement

- Launched the sustainable procurement project

- R124,4 million spent on socio-economic development (SED) initiatives

KEY PRIORITIES FOR 2014/15

Continue to promote a culture of safety in the workplace

• Extend ‘zero harm’ campaign to relevant stakeholders

• Strengthen strategic partnerships towards the development of rural sugarcane farmers

• Continue implementation of farming models that enable efficient sugarcane and maize growing and respond to the food security imperative

• Further enhance the business’s stakeholder engagement framework

EXTERNAL RECOGNITION

- Tambankulu Estates and Voermol Feeds received their 9th and 2nd Platinum Noscar Awards respectively

- The Investment Analysts Society of South Africa voted Tongaat Hulett as the winner of the Best Reporting and Communication Award in the Consumer Products category in 2013, for the sixth consecutive year.

- In 2013, Tongaat Hulett was included in the JSE’s Socially Responsible Investment (SRI) Index for the tenth year in a row.

- Tongaat Hulett has been recognised as one of the leading

companies in the Carbon Disclosure Project (CDP) Consumer

Staples category. The company’s future prospects include

opportunities within the field of renewable electricity

and biofuels.

CONTEXTTongaat Hulett has a significant presence in agriculture and agri-processing sectors in the Southern African Development Community (SADC). The company partners with communities, regulators and governments to address some of the region’s socio-economic challenges, including job creation, food security, rural development and the provision of renewable energy. |

2020 KEY STRATEGIC SUSTAINABILITY PARAMETERS The company is in its fifth year of focusing on its 2020 Key Strategic Sustainability parameters and continues to evolve on its journey as a significant role-player in the transformation of the region. Tongaat Hulett is continuously improving its sustainability data collection processes for all non-financial performance indicators and will continue to seek assurance over the most material sustainability indicators. Independent third-party assurance over key social and environmental performance indicators is viewed as an important step in ensuring that stakeholders are afforded a fair presentation of the company’s commitment to continuous improvement.

|

||||||||||||||||||||||

SUSTAINABILITY STRATEGYTongaat Hulett places significant value on being regarded as a responsible corporate citizen and strives toward creating value for its stakeholders in a responsible and ethical manner. Tongaat Hulett endorses the principles of transparency, communication and accountability as critical components of delivering on the expectations of the investment community, private farmers, local communities, governments, consumers, suppliers and employees. The company recognises that transparency and accountability in reporting are key priorities. During the reporting period there were no significant changes in the size, structure or ownership of the company. There was no significant changes in the scope, boundary or measurement methods applied in the report, and there have been no restatements of prior year data, except where LTI data for 2012 and 2013 has been updated. The company joined the United Nations (UN) Global Compact in 2012. This initiative was started in 1999 by the UN to promote good corporate citizenship and companies can, on a voluntary basis, comply and report on the principles published on the website of the UN Global Compact - www.unglobalcompact.org. The inititive comprises ten major principles from the areas of human rights, labor standards, environmental protection and measures to combat corruption, and are covered in detail in this section of the report. |

|||||||||||||||||||||||

SUSTAINABILITY INDICATORS

| INDICATOR | 2012/13 (12 MONTHS) | 2013/14 |

| Revenue | R14,373bn | R15,716bn |

| Annual dividend per share (cents) | 340 | 360 |

| Number of employees at year end | 39 246 | 35 065 |

| Fatalities | 3 | 1 |

| LTI’s | 56 | 45 |

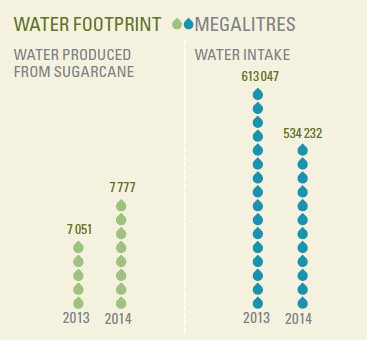

| Water intake (Megalitres) | 613 047 | 534 232 |

| Carbon footprint (metric tons of CO2-e) | 1 246 234 | 1 140 320 |

SOCIAL AND RELATIONSHIP CAPITAL

Stakeholder engagement

Tongaat Hulett promotes an open and transparent relationship with all of its key stakeholders, which is deeply entrenched in the business’s history. The company’s operations require the involvement and participation of a diverse range of stakeholders as it progresses delivery of its strategic thrusts. Tongaat Hulett’s key stakeholders have been summarised in the following table:

NATURE OF ENGAGEMENT |

PRIORITIES |

OUTCOMES |

|

| Shareholders, investors and analysts | Managed by Tongaat Hulett’s investor relations team

Annual and interim results presentations and publications Roadshows both locally and abroad Ad hoc meetings with management Annual general meeting |

Clear communication of the company’s

strategy and prospects going forward

Return on investment and growth in value |

The company continues to improve on reporting its strategy and prospects |

| Private farmers | Groups are organised according to logistical areas of operation | Maximum return in terms of revenue

received for sugarcane and maize.

Support from the company towards the long-term sustainability of private sugarcane farmers |

Access to maximum quality seed cane and

cost savings on key inputs such as fertilizer

and herbicides

The company works to unlock grant funding from relevant authorities Sustainable integrated farming model implemented across SADC region for staple foods sugarcane and vegetables |

| Government authorities and regulators | Partnerships on joint projects

Forums discussing existing and emerging initiatives Ad hoc meetings Compliance monitoring |

Compliance across operations with local,

provincial and national regulations

Effective partnerships towards achieving articulated government objectives, projects and policies Demonstrable company support towards sustainable socio-economic growth in the region |

Tongaat Hulett operates within regulatory

and compliance frameworks and has efficient

systems in place for addressing complaints

Ongoing partnership with relevant government agencies on various initiatives including sugar expansion in rural communities and land conversion activities |

| Local communities |

Regular and ad hoc local forums with

traditional and community leaders

Development of small-scale private farmers in the communal areas identified for sugarcane expansion Regular interaction at local level through the SED provision of basic needs and services |

Access to sustainable jobs and

economic opportunities

Affordable education, training and access to healthcare, basic amenities and infrastructure The conservation of the community’s way of life, culture and environment |

Additional direct and indirect jobs

Socio-economic investment addressing a broad range of needs in Mozambique, South Africa, Swaziland and Zimbabwe Health programmes for all employees extend to communities, including counselling, screening and treatment for both HIV/AIDS and malaria Ongoing schooling and infrastructure development projects involving local communities |

| Employees | Regular collaboration on topics of

employee protection, diversity and

performance rewards

A variety of internal communication channels, including the company intranet, internal newsletters and briefings |

Stable employment relationships and

job security

A working environment that guarantees health, safety, fairness and equal opportunity Opportunities for upward and sideways movement within the organisation Freedom of association and rights of collective bargaining Training and development |

Sound corporate governance practices

aligning remuneration with performance

Managers across operations interact with

trade unions in an open and constructive

manner

Ongoing healthcare programmes across rural operations, particularly in Mozambique, Swaziland and Zimbabwe |

| Customers, suppliers and service providers | Regular interaction on procurement

processes, responsible sourcing standards

and supply chain management

Regular interactions with customers regarding matters of relevance to this stakeholder |

Local procurement

High quality products at competitive prices that attract consumers and encourage brand loyalty Product innovation and growth of the business Professional and mutually beneficial trade relationships and robust supply chain mechanisms Product responsibility and food safety |

The company continuously improves the

quality, taste and innovative features of

products at reasonable prices

Tongaat Hulett operates under the relevant regulations, standards and laws to ensure the quality and safety of all its products |

Socio-economic development (SED)

Socio-economic development is an integral part of Tongaat Hulett’s operations and is closely linked to the company’s overall strategic objective of developing sustainable indigenous farms to support and grow rural communities.

The company exceeded its commitment of allocating one percent of annual headline earnings to SED for the 12 months to 31 March 2014. For this period, Tongaat Hulett invested R124,4 million (2012/13 R142, 7 million) in its SED initiatives, including the cost of company-sponsored occupational and primary healthcare services. Operations in Zimbabwe, Mozambique and Swaziland accounted for 84 percent of the total amount invested in SED initiatives. Key elements of SED spend for the period are as follows:

- Education:

- R12,7 million invested in education initiatives across the company.

- Purchase of exercise and text books, replacement of desks and chairs in all the Estate schools in Zimbabwe.

- The operations at Triangle and Hippo Valley in Zimbabwe have 22 schools - 18 primary and four secondary. The total enrolment at the schools is now some 14 400.

- Of total investment in education, R379 000 was directed at ABET training.

- Healthcare:

- With the majority of operations being located in rural areas, a significant amount is invested in running healthcare facilities for employees and local communities.

- R67,7 million invested in health-related activities during the period, of which R4,8 million was specifically allocated to dealing with the impacts of HIV/AIDS.

- Basic needs:

- R4, 9 million invested in basic needs and social development, which includes food security projects and the provision of basic materials, in order to uplift communities around company operations.

- In Zimbabwe, food security projects included the completion of the Chilonga cattle feedlot, the provision of 2 500 litres of diesel and other inputs (including five tons of sorghum and ten tons of fertiliser) to communities via the satellite Chiefs.

- Further development included the completion of St Joseph irrigation scheme projects and a water extraction scheme at Manjinji.

- Infrastructure development:

- R5,3 million was invested in infrastructure development projects as an important aspect of assisting with the development of successful rural communities such as road construction.

- • Sports, arts and culture:

- The company acknowledges the important role that arts, sports and culture can play in the development of successful rural communities. R381 000 was invested in these initiatives during the year.

Creating sustainable communities

Tongaat Hulett works in partnership with government and communities to develop sustainable communities. For more information on the Cornubia Integrated Human Settlement, visit Tongaat Hulett’s website at www.tongaat.com

Developing indigenous farmers

Zimbabwe

Successful operations in Zimbabwe are enhanced through a comprehensive private farmer rehabilitation programme with the objective of developing 15 880 hectares of private farmland under the Successful Rural Communities Project (SusCo). There are currently 813 active farmers, who employ some 6 700 people. In terms of phase two of the project, an additional 3 000 hectares of new private farmer sugarcane development will be completed from the Kilimanjaro project.

Mozambique

In the operations at Xinavane and Mafambisse, Tongaat Hulett continues to work with rural communities in order to develop indigenous sugarcane farmers. In the past season, 2 735 indigenous farmers on 6 155 private and leased hectares supplied sugarcane to Tongaat Hulett operations.

Food security

As a member of the UN Global Compact, Tongaat Hulett remains committed to accelerating its disaster risk reduction activities and seeking to make food production systems more resilient and more capable of absorbing the impact of, and recovering from, disruptive events. Many crop yields are expected to decline due to long-term changes in temperature, rainfall and increased climate variability. The outcome of these impacts on weather patterns may result in higher food prices, chronic poverty and undernourishment for farming households in rural communities. Disaster risk reduction activities ensure the protection of development investments in the agriculture, livestock, and forestry sectors, thereby providing assistance to vulnerable communities and assisting in food security.

Supply chain

Tongaat Hulett is committed to sustainable and innovative procurement initiatives to deliver value to the business and local communities in which it operates. In order to achieve alignment and sustained benefits, high level cross-functional teams involving Strategic Sourcing, Human Resources, SHE and business operations are working closely on sourcing projects with potential to deliver positive economic, social and environmental outcomes, including:

- Project SETH (Sourcing Excellence in Tongaat Hulett) - a fundamental reconfiguration and transformation of the company’s approach to procurement.

- Local Procurement and Enterprise Development Projects - a set of policy guidelines to accelerate the visibility and impact of local procurement and enterprise development projects in the various countries in which the company operates. Special attention is being directed to provide local start-ups and Small to Medium Enterprise (SME) suppliers with preferential access to supply opportunities inherent in Tongaat Hulett’s extensive value chain in order to improve employment opportunities for local communities.

- Green Procurement Initiatives – a good business imperative that suppliers of the company demonstrate commitment to research, development and delivery of safer, resourceefficient and environmentally-friendly goods and services. Of particular interest are current trials of organic fertilizers which, if successful, could replace chemical-based fertilizers on a wider commercial scale.

Preferential procurement

The objective of Preferential Procurement under the Department of Trade and Industry’s current Codes of Good Practice (in South Africa) includes the promotion of BEE compliance by all entities and targets for procurement from Exempted Micro Enterprises (EME’s), Qualified Small Enterprises (QSE’s), black-owned and black women-owned enterprises. Furthermore, with enhanced recognition given for Preferential Procurement from value-adding suppliers and enterprise development beneficiaries, the procurement of locally-produced goods and services is actively supported, to assist in developing sustainable income streams for such new entities.

Tongaat Hulett is committed to supporting suppliers, improving their empowerment credentials and introducing SME’s, black-owned and black women-owned suppliers to the business. The company’s Preferential Procurement score during the previous assessment period was 14,37/20. In respect of the Procurement Scorecard for Tongaat Hulett, and based on the expenditure for the period ending 31 March 2013, out of a total available spend (defined as total procurement spend less spend on parastatals and imported goods) of R7,349 billion, BEE procurement spend from all suppliers based on BEE procurement recognition levels as a percentage of total measured spend, was R5,336 billion (72,61 percent). Spend with QSE and EME suppliers totalled R965 million whilst spend with black-owned EME suppliers totaled R114 million and total spend with black womenowned EME’s was R36 million.

| 14,37/20 | Preferential procurement score during the previous assesment period | |

| 72,61 | Percentage of total available spend on BEE procurement spend | |

| R965 Million | Spend with QSE and EME suppliers | |

| R114 Million | Spend with black-owned EME suppliers | |

| R36 Million | Spend with black womenowned EME suppliers |

Transformation

Tongaat Hulett has a long history of being socially active in the

SADC region and proud of the fact that it has met its internal

transformation targets. The sixth B-BBEE rating audit by AQRate

was conducted in 2014, with Tongaat Hulett being categorised

as a Level Three Contributor and scoring 81,51%. The challenge

will be to maintain this rating as the business transitions to the

Agri-BEE Generic Scorecard rating with more stringent

benchmarks.

Tongaat Hulett has a long history of being socially active in the

SADC region and proud of the fact that it has met its internal

transformation targets. The sixth B-BBEE rating audit by AQRate

was conducted in 2014, with Tongaat Hulett being categorised

as a Level Three Contributor and scoring 81,51%. The challenge

will be to maintain this rating as the business transitions to the

Agri-BEE Generic Scorecard rating with more stringent

benchmarks.

Safety, Health and Environment (SHE)

The Chief Executive Officer and senior management oversee allocation of appropriate resources and provide guidance on implementation of SHE improvement programmes. Progress on SHE performance is reviewed at various levels of the organisation including the Board’s subcommittee on Risk/SHE/Socio/Ethics and various SHE committees led by executives responsible for all business operations.

With a peak employee complement of some 35 000 people, working with various stakeholders and operating in different communities with diverse cultural backgrounds, human behaviour dynamics provide a critical link to Tongaat Hulett’s safety risk management framework, which includes contractors.

The company is focused on progressing a ‘zero harm’ campaign to promote a safe behavioural culture that goes beyond being conscious of safety to being and feeling subconsciously safe with the support of other individuals at the workplace, at home and in social environments. |

The company’s safety performance continues to improve in terms of both fatalities and injuries. A single work-related fatality was regrettably suffered in the 2013/14 fiscal year resulting in a Fatality Injury Frequency Rate (FIFR) of 0,002 compared to a FIFR of 0,005 recorded in 2012/13. While this fatality is deeply regretted and ‘one too many’, a reduction in the number of fatalities suffered from three recorded in 2012/13, two in 2011/12 and four in 2010/11 reflects encouraging progress towards the total elimination of work-related fatalities. Significant fatality risks were identified and their respective controls have been implemented if they were not already in place. Notwithstanding the fact that existing fatality risk controls are deemed to be appropriate, a continuous risk assessment review protocol is available and being adhered to by all operations.

A total of 45 Lost Time Injuries (LTIs) were recorded in 2013/14 compared to 56 suffered in 2012/13 representing a 20 percent reduction. A Lost Time Injury Frequency Rate of 0,087 was recorded. An encouraging improvement of LTIFR was observed during the past five years as shown in the table above. A total of 462 medical treatment cases and 939 first aid cases were recorded in the year resulting in a Total Recordable Cases Frequency Rate (TRCFR) of 0,98 and Total Injury Frequency Rate (TIFR) of 2,80 respectively. Total injuries of 1 447 recorded in 2013/14 represented a 15 percent reduction from 1 707 suffered in the previous year. High order safety interventions that included the establishment of hard barriers and engineering solutions in mitigating risks were applied during the year and have made a positive impact on safety performance.

| Actual 12 months to 31 March 2012 |

Actual 12 months to 31 March 2013 |

Actual 12 months to 31 March 2014 |

Limits 12 months to 31 March 2015 |

|||||

| LTIs | LTIFR | LTIs | LTIFR | LTIs | LTIFR | |||

| Sugar | 53 | 0,09 | 47 | 0,08 | 39 | 0,08 | LTIFR | 0,07 |

| Starch | 6 | 0,40 | 9 | 0,58 | 6 | 0,39 | LTI | 4 |

| Developments | 0 | 0,00 | 0 | 0,00 | 0 | 0,00 | LTI | 0 |

| Consolidated | 59 | 0,10 | 56 | 0,094 | 45 | 0,087 | LTIFR | 0,093 |

Food safety

Tongaat Hulett has, over many decades, developed a reputation as being a producer of high-quality products. In order to ensure that this reputation is maintained, the company manages its maize requirements on a non-genetically modified basis using a sophisticated identity preservation system. The use of this system enables the company to meet the needs of its customers in the food industry. In addition, ongoing attention is paid to the requirements of ISO 9001, the Hazard Analysis Critical Control Point system (HACCP) and ISO 22000, in terms of quality and food safety standards at all operations. These systems are in various stages of being certified by the South African Bureau of Standards (SABS).

Sugar or sucrose is a completely natural plant product. It is produced by the sugarcane plant in much the same way as other plants produce sugars in fruit or vegetables. In the body, the sucrose molecule separates into glucose and fructose, exactly the same sugars that are found in fruit. Neither white nor brown sugar contains additives or preservatives of any kind.

Consumption of any foodstuff, no matter how harmless, at excessive levels, especially if it is to the exclusion of other types of food, is not conducive to good health. As part of a sensible, balanced diet, sugar is a natural and healthy contributor to the enjoyment of food.

Health

Public health and employee well-being remain key strategic fundamentals within Tongaat Hulett. This continues to be managed primarily through comprehensive healthcare programmes that include occupational health, primary health and general wellness.

HIV and AIDS

HIV and AIDS continue to present a significant challenge for Tongaat Hulett and the communities in which it operates. Programmes that include Voluntary Counseling and Testing (VCT), HIV Counseling and Testing (HCT) and Anti-Retroviral Treatment (ART) continue to be offered by the company in addition to varying models of HIV/AIDS management already established at the various operations. Male Medical Circumcision (MMC) is a preventative measure that has been shown to reduce transmission of HIV in men by up to 60 percent and has been established at most of the business’s operations. More than 85 percent of Tongaat Hulett’s employees presented for VCT/HCT during the year. In addition, a total of 14 818 contractor employees presented for VCT/HCT offered for free by the company. The number of employees and contractor employees enrolled on the company’s ART programme during the year was 3 493 and 877 respectively. This represents a total of 4 370 people being offered ART by the company at a cost of R2 066 585.

The success of the ART programme has also resulted in more HIV positive employees remaining at work as opposed to leaving employment through death or medical retirement.

Malaria

The company operates in high malaria risk areas in Zimbabwe, Mozambique and Swaziland. Employees and communities in these countries are therefore vulnerable to the disease. Tongaat Hulett is in partnership with the respective regulatory authorities and non-governmental organisations in managing various malaria control programmes that include indoor residual insecticide spraying, larviciding, chemo-prevention with Deltaprim, use of mosquito repellents and long-lasting insecticide-treated mosquito nets. Community-based health education awareness campaigns at these operations are ongoing.

No malaria-related fatalities were recorded in 2013/14. There was a 33 percent increase in the number of malaria cases recorded in 2013/14 when compared to the previous year. The increase was attributed to environmental factors including unusually heavy rainfalls that resulted in flooding in Zimbabwe and Mozambique. Socio-economic factors that resulted in expanded informal settlements unfortunately limited the effectiveness of householdbased insecticide spraying interventions.

NATURAL CAPITAL

Environmental stewardship

Globally, natural resources are under stress and ecosystem degradation is a material issue to all businesses, given the significance of sustainable natural capital to global socio-economic prosperity. As an agricultural company, Tongaat Hulett is a major user and owner of land, biodiversity and water resources. Tongaat Hulett embraces the sustainability imperative of conducting business in an environmentally-conscious manner.

Climate change

Climate change creates risks and opportunities for the company and may ultimately lead to significant changes in the physical environments in which businesses operate. Management believes the global energy and climate challenges are best met by companies, governments and society working together. Energy demand growth will require increased energy efficiency, and the use of all available energy sources: fossil fuels, nuclear and renewable energy sources.

Given the increased focus on climate change, Tongaat Huletthas an objective of changing its emissions profile and improving energy and GHG-intensity of its operations. The generation of renewable electricity from bagasse and the blending of biofuel with petrol and diesel will help consumers to lower their GHG emissions.

The business is committed to reducing its greenhouse gas emissions by five percent per annum for the next five years and is targeting at least a 20 percent reduction by 2020 from a 2013 baseline. |

Carbon management

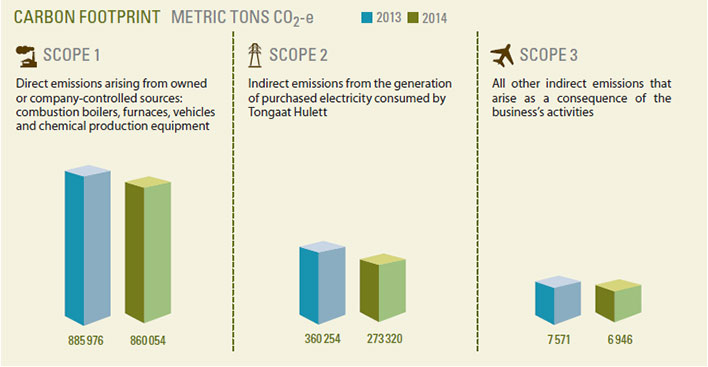

Climate change is integrated into the business’s company-wide risk management processes and a detailed discussion on this important topic is included in Tongaat Hulett’s latest submission to the Carbon Disclosure Project (CDP). The CDP is an independent initiative encouraging transparency on all climate changerelated issues and providing details of emissions performance. As part of the CDP process, the company conducted its fifth carbon footprint analysis which was conducted according to the Greenhouse Gas Protocol, a widely used international accounting tool. Details of the company’s actions underway are provided in the public response to the CDP (www.cdproject.net). Tongaat Hulett tracks and monitors its GHG emissions and will continue to improve the accuracy and reporting of its carbon footprint.

During the year, business operations emitted 860 054 metric tons CO2 equivalent (CO2-e) Scope 1 emissions. The company purchased electricity that emitted 273 320 metric tons of CO2-e. The total Scope 3 emissions were 6 946 metric tons CO2-e covering business travel, supply chain transport and distribution by third party companies. In the reporting period, employees booked nearly 2 000 business trips, flying more than 3,4 million

kilometers, resulting in 703 metric tons CO2-e being emitted from business travel.

The total Scope 1, Scope 2 and Scope 3 carbon emissions for the period under review was 1 140 320 tons CO2-e and the turnover was R15, 716 billion, which equates to 73 grams of CO2 emitted per Rand generated. The GHG emissions have been verified by a third party service provider.

Total emissions from South African operations, calculated at 749 529 metric tons CO2-e, includes emissions of 393 016 metric tons CO2-e emanating from the South African sugar operations. Tongaat Hulett recently completed a study with the assistance of carbon specialists which found that the company’s sugar farms sequest carbon at a rate of 12 tons per hectare per annum from sugarcane produced. Using this rate, Tongaat Hulett’s 35 035 hectares (grown from company-owned and leased land) equates to 420 420 metric tons sequested CO2-e per annum. The South African sugar operations could benefit from the carbon capture and storage of CO2 in the growing of sugarcane if the National Treasury allows for sequested emissions to be deducted from the company’s carbon footprint.

Consequently, this part of the business should be well placed to offset a substantial part of its emissions on this basis, resulting in South African operations emitting a net 329 109 metric tons CO2-e overall. |

Energy

The imminent introduction of a suitable regulatory framework

for the provision of privately-produced alternative energy to the

national grid in South Africa could potentially result in Tongaat

Hulett expanding the business’s ability to generate electricity

from bagasse, a renewable resource produced as a co-product of

the sugar refinement process. In the short to medium term, this

would involve infrastructure development projects across the company’s sugar mills in order to more than double capacity for

energy generation from bagasse.

The imminent introduction of a suitable regulatory framework

for the provision of privately-produced alternative energy to the

national grid in South Africa could potentially result in Tongaat

Hulett expanding the business’s ability to generate electricity

from bagasse, a renewable resource produced as a co-product of

the sugar refinement process. In the short to medium term, this

would involve infrastructure development projects across the company’s sugar mills in order to more than double capacity for

energy generation from bagasse.

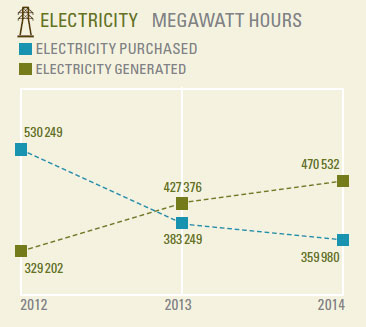

For the period to 31 March 2014, Tongaat Hulett used 784 397 MWh of electricity in all of its operations and offices. It generated 470 532 MWh from its sugar mills, predominantly from bagasse, and sold 45 930 MWh to the national grid. In the previous reporting period ended 31 March 2013, Tongaat Hulett used 774 302 MWh, generated 427 376 MWh and sold 36 323 MWh. Other sources of fuel that are used include coal (295 740 tons), diesel (12 343 725 litres), petrol (1 097 981 litres), gas (472 293 KJ) and wood.

Air quality

Sugar mills primarily burn bagasse as a fuel and, as a result, the flue gases from the boilers do not contain harmful levels of contaminants. Wet scrubbing technology is used to remove fly-ash from the flue gas to ensure that emissions meet the required air quality standard. The recent South African legislative changes to air quality standards are far more stringent and present a challenge for the sugar industry as a whole and an appropriate action plan to ensure compliance with new standards has been formulated. All South African sugar operations have submitted applications for their Air Emission License and are awaiting feedback from the relevant authority. During 2014, the milling operations have trialed the use of woodchips as a supplementary fuel option to deal with low cane throughputs periods. The trials were successful and have provided an alternative to coal-based fuel.

Some sugar mills and in particular the central sugar refinery in the Durban South Industrial Basin burn coal as a boiler fuel and therefore have a greater challenge in terms of emission reduction, as required by the recent legislative amendments. The refinery has been issued with a five year schedule trade permit which has incorporated the latest air quality standards based on its rated capacity. The revised emission targets have been based on the development of innovative process technology which will have significant energy efficiency benefits. The construction of the R18m demonstration plant to test the new proposed process technology has been completed. The project is now due for commissioning which will take place during 2014.

During 2013, the refinery initiated two projects aimed at reducing its overall carbon footprint. The first project involved the cross-haul of sugar during the milling off-season via rail, thereby reducing the impact of road transport. The second initiative was the complete replacement of the forklift fleet for sugar movement in the warehousing operations resulting in a 14 percent reduction in diesel usage.

Biodiversity and land management

External expectations around the private sector’s management of biodiversity are growing. Tongaat Hulett’s activities impact biodiversity, making agricultural and land development projects increasingly high profile and sensitive for communities, governments, investors and other interested parties. The company controls over 20 000 gross hectares of land in South Africa, of which some 8 200 developable hectares have been assessed as having high potential for conversion from agriculture to other uses at the appropriate time. This conversion is carefully managed in a coordinated and planned manner in line with broader government objectives and spatial policies. At the same time the company continues to rehabilitate currently unproductive land to agriculture in support of government’s agricultural and rural development goals and objectives, while also securing additional sugarcane supply to its mills.

Water resource management

Tongaat Hulett is involved in water partnership projects addressing locally relevant issues such as watershed protection, access to safe drinking water, sanitation, agricultural water efficiency, and education and awareness.

Management is increasingly addressing water stewardship in the context of the “water-energy-food” nexus through an integrated approach informed by the CDP Water Disclosure, the 2030 Water Resources Group (2030 WRG), and the National Water Resources Strategy released by the South African Department of Water Affairs. The business is a signatory of the UN Global Compact CEO Water Mandate and is committed to effective water resource management throughout its operations.

The company has a Water Policy in place which documents Tongaat Hulett’s approach to key water management elements, including effective use of water resources, local water resource optimisation and protection. |

The company continues to identify opportunities for water

recycling, efficient use and responsible wastewater disposal. Sugar

mills in South Africa are net producers of water due to the fact

that the sugarcane plant comprises approximately 70 percent

water. Most of the sugarcane cultivated in South Africa is

dependent on natural rainfall, while operations in Mozambique,

Swaziland and Zimbabwe practice large-scale irrigation via

purpose-built canal systems with water being extracted from

rivers. The management of these canals and irrigation systems is

in keeping with the highest agronomy and safety standards.

The company continues to identify opportunities for water

recycling, efficient use and responsible wastewater disposal. Sugar

mills in South Africa are net producers of water due to the fact

that the sugarcane plant comprises approximately 70 percent

water. Most of the sugarcane cultivated in South Africa is

dependent on natural rainfall, while operations in Mozambique,

Swaziland and Zimbabwe practice large-scale irrigation via

purpose-built canal systems with water being extracted from

rivers. The management of these canals and irrigation systems is

in keeping with the highest agronomy and safety standards.

The input water sources include water abstracted from rivers, water available in sugarcane and water purchased from municipal sources. Most sugar mills operate in remote locations and therefore assist in the provision of potable water to local communities. For the reporting period, the total water input was 514 232 Ml of which 7 777 Ml was produced from sugarcane and 8 352 Ml was supplied to communities or sold to local municipalities.

Effluent

Subsequent to the ‘zero effluent` philosophy that has been adopted by several operations to minimise the quantity of liquid effluent leaving each mill or plant, most of Tongaat Hulett’s sugar mills recycle and re-use water within the factories, while the remaining effluent undergoes biological treatment (aerobic and anaerobic) to reduce its chemical oxygen demand to acceptable levels before being discharged in accordance with the relevant environmental requirements. The remaining mills are developing environmental management programmes to adopt best practices and ensure legal compliance as a minimum. Water that is produced as part of the sugar milling process is largely used for the irrigation of sugarcane on adjacent estates and effluent produced at the central sugar refinery is disposed of into the municipal sewer for treatment, and both the quantity and quality thereof is monitored to ensure compliance with the relevant specifications.Waste management

Some company operations have re-engineered and refined services in order to reduce waste and increase resource productivity and these initiatives have yielded new revenue streams from the sale, exchange and recycling of waste products. A significant increase in recycled material volumes was noted for this reporting period. Some of the new practices implemented include the recycling of cane spillage from roadways back into farming.

The increase in hazardous waste volumes is mainly attributed

to the re-classification of boiler ash at Triangle and Hippo

Valley. The residual chemical content in boiler ash has resulted

in the `hazardous’ classification. This is most likely linked to the

source of coal being used at these two operations. During the

reporting period, 12 824 tons of general waste (2013: 11 436 tons),

2 803 tons of scrap metal waste (2013: 4 152 tons) and 4 359 tons

of hazardous waste (2013: 3 084 tons) was generated and

disposed of in accordance with applicable legislation.

The increase in hazardous waste volumes is mainly attributed

to the re-classification of boiler ash at Triangle and Hippo

Valley. The residual chemical content in boiler ash has resulted

in the `hazardous’ classification. This is most likely linked to the

source of coal being used at these two operations. During the

reporting period, 12 824 tons of general waste (2013: 11 436 tons),

2 803 tons of scrap metal waste (2013: 4 152 tons) and 4 359 tons

of hazardous waste (2013: 3 084 tons) was generated and

disposed of in accordance with applicable legislation.

Environmental compliance

During the year, the company dealt with a number of concerns raised by affected stakeholders surrounding its operations. There were no material incidents or non-monetary sanctions for noncompliance with applicable environmental regulations during the year under review. The established community liaison forums between Tongaat Hulett and interested parties continue to address environmentally-related complaints. Below is a summary of how the issues were addressed and resolved:

- The Maidstone mill in Tongaat was issued with a directive by the municipal official in September 2013 relating to the overflow of effluent during a sludge removal activity at the effluent dam. The mill was asked to develop a plan for effective management of the effluent dam. This plan was submitted and acknowledged by the regulatory authority. The mill continues to proactively engage with local communities and the relevant authorities on matters related to effluent irrigation. Several short-term initiatives have been put into place to deal with community concerns.

- The Department of Environmental Affairs (DEA) issued a fine to Tongaat Hulett for disturbing virgin land in the KwaMthethwa traditional leadership area where the cane and rural development unit (CRDU) was operating. While it had been acknowledged that Tongaat Hulett’s agriculture operations caused some disturbance on virgin land, management took a decision to appeal against the level of the fine considering an existing partnership involving Tongaat Hulett, the DEA and the KwaMthethwa Traditional Council. An appeal decision has since been received from the DEA, in which the extent of the original fine was significantly reduced. In the interim, efforts continue to be directed at avoiding tampering with virgin land during agriculture operations. Visit Tongaat Hulett website at www.tongaat.com for more detail.

- A total of 50 complaints (48 - level 1 and two - level 2) were recorded during the year.

The following is a summary of how the more severe (level 2) complaints were addressed and resolved:

- The Developments operation received a complaint regarding the pruning of trees at the business’s office. The incident, which attracted local media attention, was addressed by the operation.

- The Starch milling operations received complaints relating to effluent and odour from process operations. Corrective action was taken to address all matters that were raised and the measures taken included the submission of an environmental management plan and the upgrading of process operations to deal with these complaints.

HUMAN CAPITAL

Tongaat Hulett’s strategic aspirations and operating business

plans informs the company’s human capital planning and directs

the human resources interventions rolled out at all levels of the

company. In all the geographies in which we operate, the local,

regional and global dynamics; and most importantly the various

national socio-economic, regulatory, legislative and other factors

are taken into consideration when managing the company’s human

resources. Given this context of managing internal and external

operating factors, strategic decisions on the management of

company human resources is provided centrally by the company’s

leadership, while the implementation of HR interventions is

localized to ensure relevance and direct and immediate impact on

company’s plans and operations.

Tongaat Hulett’s strategic aspirations and operating business

plans informs the company’s human capital planning and directs

the human resources interventions rolled out at all levels of the

company. In all the geographies in which we operate, the local,

regional and global dynamics; and most importantly the various

national socio-economic, regulatory, legislative and other factors

are taken into consideration when managing the company’s human

resources. Given this context of managing internal and external

operating factors, strategic decisions on the management of

company human resources is provided centrally by the company’s

leadership, while the implementation of HR interventions is

localized to ensure relevance and direct and immediate impact on

company’s plans and operations.

For the reporting period, priority was given to leadership and executive resources as well as other critical skills in the various operations. Interventions were also focused on employee welfare, and on creating an environment conducive for industrial relations through engagement with the various labour and employee representation formations. Employee training and development remains the backdrop for ensuring continuous improvement in our operations, enhancing individuals’ knowledge and skills, as well as to provide career development opportunities for our employees.

The company continues to provide a competitive value proposition to attract, employ, retain and develop good caliber and diverse employees who are able to contribute to the achievement of the business’s strategic goals.

Employee base

The total workforce as at 31 March 2014 across all countries was 35 065 compared to a total of 39 246 the previous year. This includes full-time employees, seasonal and casual workers as well as fixed-term contractors. The downward change in the number of employees was through managed recruitment and attrition.

The breakdown of Tongaat Hulett’s employee base per country as at 31 March 2014 is as follows:

| Operating country |

Full-time & fixed-term employees |

Seasonal workers & casuals |

Total |

| South Africa | 3 326 | 1 606 | 4 932 |

| Mozambique | 8 467 | 6 878 | 15 345 |

| Zimbabwe | 11 836 | 1 886 | 13 722 |

| Swaziland | 403 | 355 | 758 |

| Botswana | 118 | 3 | 121 |

| Namibia | 174 | 13 | 187 |

| Totals | 24 324 | 10 741 | 35 065 |

Existing specialised skills in all countries

The company’s operations rely on different types of skills and competencies, primarily in agriculture, milling and refinery, marketing, sales, distribution and commercial skills; as well as engineering and technical skills. These skills groups generally tend to be difficult to attain from the labour market, they require longer term investment in training and development, they are highly specialized for cane/sugar and maize/starch agro-processing functions, and are highly mobile in terms of employability, therefore requiring investment in training and posing retention challenges. Focus is therefore given to these highly qualified and highly skilled individuals. The interventions to maintain the required capacity are aimed at improving skills of current employees, attaining from the labour market; while building future capacity through graduate development programmes such as the engineers in training project.

In the various critical functional areas, the breakdown of qualifications of these specialized skills across the company is as follows:

Number |

Average age |

Number terminated |

Number appointed

|

|

| Degrees/ Diplomas |

1 155 | 40 | 76 | 49 |

| Artisans |

496 | 40 | 29 | 21 |

Human Capital Interventions

Succession Planning and Critical Skills Talent Management

There has been focus on the leadership, executive resources and critical skills of the company, and significant progress has been made in managing key talent for executive leadership and other critical roles across the company.

A formalized process for managing the company’s top talent in key roles is in place at company level for cross-company leadership and key roles requirements, while each operating company has talent management processes for operations’ specific skills requirements and to provide long-term skills needs

for the company. Talent management incorporates succession planning, talent development and talent retention aimed at building capacity for both immediate and long-term skills needs. The company’s key talent has been ‘segmented’ and prioritized, based on business skills needs and challenges, key roles, individuals’ performance and potential, as well as in line with employee transformation aspirations in Mozambique, South African and Zimbabwean operations. The diversity of skills in the businesses talent pool is steadily improving, including females being appointed into the senior and executive leadership roles in South Africa and Zimbabwe so far.

Talent management programme interventions are proactive and dynamic, as they continuously re-calibrate skills and capacity requirements and an ongoing identification of talented individuals from within the entire employee base, and providing development experiences and support for each employee to reach their potential.

There has been focus on the leadership, executive resources and critical skills of the company, and significant progress has been made in managing key talent for executive leadership and other critical roles across the company. |

Employee Training & Development

The employee training and development interventions are

informed by business needs, operating challenges, existing skills

supply and levels of competence, against the skills requirement

for each of the operating companies. The interventions that

were prioritized for the reporting period include artisan training,

graduate development programmes, supervisory skills training,

agriculture management skills and Safety, Health and Environment

(SHE) training. Agriculture skills training, motorised equipment

(such as fork-lifts) training, and SHE training received the highest

priority, in line with operations goals and continued focus on

employee safety and welfare. Furthermore, employees were

provided opportunities to study further through the employee

study support scheme, improving their skills and career

opportunities. Spend on training and development for the year

exceeded R50 million.

The employee training and development interventions are

informed by business needs, operating challenges, existing skills

supply and levels of competence, against the skills requirement

for each of the operating companies. The interventions that

were prioritized for the reporting period include artisan training,

graduate development programmes, supervisory skills training,

agriculture management skills and Safety, Health and Environment

(SHE) training. Agriculture skills training, motorised equipment

(such as fork-lifts) training, and SHE training received the highest

priority, in line with operations goals and continued focus on

employee safety and welfare. Furthermore, employees were

provided opportunities to study further through the employee

study support scheme, improving their skills and career

opportunities. Spend on training and development for the year

exceeded R50 million.

Compliance with Legislation & Regulations in Employee Management

Tongaat Hulett complies with the various legislative and regulatory frameworks with regards to employee management and skills development reporting. The information below, is presented in terms of South African legislation, and therefore excludes other company operating geographies.

The various categories of training and development courses are in the table below:

| Categories of training programmes |

Number of employees who attended training |

Percentage |

| Management and supervisory skills |

429 | 3,0% |

| Agricultural skills |

3 671 | 25,7% |

| Engineering/Technical /Artisan |

745 | 5,2% |

| SHE |

6 690 | 46,8% |

| Driver-Forklift/ Crane/Tractor |

2 055 | 14,4% |

| Human resources training |

129 | 0,9% |

| Life skills |

125 | 0,9% |

| Admin/Business skills/Finance |

456 | 3,2% |

| Total | 14 300 |

Training and related information in respect of South African Operations for the period 1 April 2013 to 31 March 2014

The operating companies in South Africa, which incorporate Sugar, Starch, and Developments, comply with the various employment legislation relating to affirmative action, employment equity, labour relations, skills development and other relevant laws. Within the overall training costs of R45,3m; a total of R28,1m was training costs for the South African operations, with the different categories of spend detailed below:

| 1 percent skills levy | R12,3 million | |

| Training spend as a % of leviable amount | 2,3% | |

| No of person days trained | 6 934 | |

| Number of person days available | 1 222 590 | |

| % trained person days | 0,6% | |

| No of persons trained | 1 453 | |

| Expenditure on African, Coloured & Indian employees | R23 399 803 | |

| Expenditure on African, Coloured & Indian Women | R6 247 327 | |

| Expenditure on employees with disabilities | R140 958 |

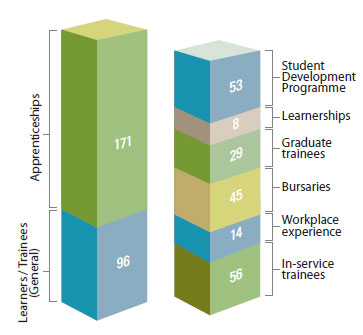

Graduate Development Programme

In line with the company’s goal of managing skills supply proactively, the graduate development programme continues to receive focused attention. Tongaat Hulett has rolled out interventions such as further education bursaries, engineers in training (EIT), in-service training and learnerships, targeting graduates from universities, further education institutions and universities of technology.

The various interventions, which are longer-term and varied based on skills needs in different operations, also take cognizance of the local socio-economic factors impacting education and training of school-leavers and further education graduates, job opportunities and levels of business knowledge and employment readiness among graduates. The company had 472 school-leavers and graduates in training, at various levels of exposure and development. These interventions are of different lengths, and are structured in line with company skills needs, university in-service requirements, and on work-readiness levels and knowledge of graduates. Apprenticeship, which is directly related to artisan and technical skills requirements, received priority.

CASE STUDY

ANDREW GIELINK When Andrew heard about

a vacancy for an Electrical

Engineer in the Technology & Engineering Group at

Tongaat Hulett in 2008

he jumped at the chance

of a mid-career change.

Andrew’s uncle, Murray

Gielink, had worked for

many years as an electrical engineer in the sugar industry

and had shared many stories of working in this challenging

and fulfilling environment, making this seem like an ideal

opportunity.

|

Summary of trainees:

Persons with Disabilities Tongaat Hulett is committed to providing a work environment that supports people with disabilities, and the Company is putting in place interventions to ensure that they reach their potential and contributes fully to the running of the functions in which they work.

There were 68 employees with disabilities as at 31 March 2014 in South Africa, which constituted 1,4 percent of the total employee complement.

Employee Diversity: Indigenization, Localization, Employment Equity & Affirmative Action

The objective to transform the diversity and employee profile of the company’s employee base informs various specific interventions across the business. Specific interventions and processes were put in place, taking into account the various operating environments and specific skills supply and challenges of the various geographies in which we operate. While all operating companies and geographies pay attention to employee transformation and diversity, the prioritized geographies for employee transformation interventions for the reporting period were Mozambique, South Africa, and Zimbabwe.

In South Africa, in response to the need to address the imbalances of the past; a strong employment equity culture has been fostered over many years. There has been steady and significant achievements in the various segments, as illustrated by improvements in the representation of designated groups, with particular emphasis on Africans, black women and persons with disabilities. As at 31 March 2014, 62,3 percent of management and 84,6 percent of skilled and supervisory positions are filled by black employees. Women constitute 29,9 percent of the workforce across South African operations. In terms of the professional skills profile, 76,1 percent of the graduates and diplomates employees are black, with women constituting 46,8 percent.

The overall proportion of black representation in management as at 31 March 2014 was 62,3 percent of permanent staff at this level, compared to 61,2 percent as at 31 March 2013. Females at senior management level increased from 14,5 percent to 16,2 percent as at 31 March 2014, the proportion of black females in top management increased from 22,2 percent to 28,0 percent as at 31 March 2014 and black females in management increased from 20,9 percent to 22,2 percent in March 2014.

In Mozambique, employee transformation is focussed on localisation of the skills base, within the legislated quotas of the government of Mozambique. Proactive processes were rolled out to identify skilled local nationals within the company and in the external labour market. There is also accelerated training and development of local nationals, ensuring that time to full productivity (where required) is shortened. Furthermore, focus will be on the gender diversity of the employee base.

In line with the company’s employee transformation aspirations, vacancies although limited during the reporting period; were utilized as opportunities for recruitment and promotion of locals and females in Mozambique, for recruitment of females into senior roles in Zimbabwe, and for females and Africans into senior roles in the South African operations. The intention is to have a diverse supply of highly skilled individuals for all key roles in the company in our targeted operating geographies, managed proactively and coordinated to ensure adequate labour supply, critical skills retention and provide career development opportunities for all employees.

Industrial relations

Human rights

Within its sphere of influence, Tongaat Hulett implements protection for basic human rights. The company is a signatory to the Universal Declaration of Human Rights, in which it commits, among others, to supporting the freedom of association and collective bargaining at its locations, as well as preventing child and/or forced labour. Tongaat Hulett has incorporated human rights principles in its practices, and operates within a Code of Business Conduct and Ethics, which supports its commitment to a policy of fair dealing, honesty and integrity in the conduct of its business. This is based on a fundamental belief that business should be conducted honestly, fairly and legally. These guidelines and operating philosophies are embedded in the company’s operating ethos, and the company expects all employees to share its commitment to high moral, ethical and legal standards.

Child labour, forced and compulsory labour

Tongaat Hulett does not make use of child labour and does not tolerate the inhumane treatment of employees, including any form of illegal forced labour, physical punishment or other abuse.

Freedom of association and collective bargaining

Tongaat Hulett employees have the right to freedom of association. This right is also entrenched in the company’s code of ethics, business principles and policies. The company has always strived to maintain a constructive relationship with unions and a climate of industrial peace has generally prevailed. There are recognition agreements with 11 different unions as at 31 March 2014 and approximately 75,5 percent of permanent employees are members of unions.

Botswana

- • Botswana Beverages and Allied Workers Union (BBAWU)

Mozambique

- • Sindicato Nacional dos Trabalhadores da Industria Do Açucar e Afins (SINTIA)

Namibia

- • Namibian Food and Allied Workers Union (NAFAU)

South Africa:

- Food and Allied Workers Union (FAWU)

- National Sugar and Refining and Allied Industries Employees Union (NASARAIEU)

- South African Agricultural Plantation and Allied Workers Union (SAAPAWU)

- United Association of South Africa (UASA)

- National Union of Public Service and Allied Workers (NUPSAW)

- Swaziland – Swaziland Agriculture and Plant Workers Union (SAPWU)

Zimbabwe:

- Zimbabwe Sugar Milling Industry Workers Union (ZSMIWU)

- Zimbabwe Hotel and Catering Workers Union (ZHCWU)

There was one strike incidents which resulted in seven days lost in Sugar SA, with a financial cost implication of R13,7 million for the period under review.

Disciplinary procedures

The disciplinary codes and procedures make provision for corrective behavior and have been drawn up in order to apply discipline in a just, equitable, non-discriminatory and consistent manner, in line with the relevant labour legislation. If any employee feels unjustly treated, they are entitled to exercise their rights in terms of the particular operation’s internal appeal procedure and the relevant legislation. Disciplinary codes and procedures have been implemented at local operations, after negotiations with the relevant trade unions.

Grievance procedures

The company’s grievance procedures are intended to create an environment that is conducive to good employee relations, by facilitating prompt and fair action by the company when employees raise legitimate complaints. The intention of the grievance procedures is to ensure that grievances are resolved as near to their point of origin as possible, and within a reasonable time frame.

Anti-Bribery and Corruption

The upholding of Tongaat Hulett’s core values requires that the business actively works to prevent corruption and bribery. The organisation has procedures in place that provide guidance on areas such as dealing with gifts and donations. Employees of Tongaat Hulett who do not comply with the company’s Code of Ethics policy face disciplinary action, including dismissal or termination of their contract.

MANUFACTURED CAPITAL

Promoting sustainable agriculture

Promoting agricultural sustainability is a socio-economic imperative. The company has policies in place that review the planning and integration of land management in light of the multifunctional aspect of agriculture, particularly with regard to food security and sustainable development.

This integrated approach involves the following:

- the participation of affected communities

- the promotion of human resource development for sustainable agriculture

- improving farm production and farming systems through diversification of farm and non-farm employment and infrastructure development

- land-resource planning information

- education for agriculture, land conservation and rehabilitation

- sustainable plant nutrition to increase food production

The company practices a range of conservation methods and land use plans to ensure that every field is environmentally assessed before planting. In selected areas, depending on soil conditions and other agronomic influences, a range of cover crops are used to improve soil conditions and nitrogen prevalence for the subsequent sugarcane crop. The company’s view is that better farming practices will halt and in some instances reverse the process of soil degradation. At the same time, farmers are encouraged to use existing farmland more efficiently. Sustainable farming solutions include not tilling the land, crop rotations, bringing vegetation back to degraded land and planting vegetation around fields to prevent erosion.

Product responsibility

Tongaat Hulett continues to participate in a number of initiatives that promote product responsibility in agriculture, agriprocessing and land development. The company complies with all relevant safety, health, environmental and quality legislation in each of the countries of operation while striving to implement industry best practice. The production facilities have been certified under the ISO 9001:2008 quality management system. In South Africa, the operations have adopted HACCP, where appropriate. Downstream products supplied to the pharmaceutical industry are required to meet the Food and Drugs Act standards.

Tongaat Hulett ensures that appropriate information is provided to its customers. All product labels contain information about the product, in compliance with the respective country legislation and labeling regulations. In addition to protecting the company, product labeling informs consumers about the product’s nutritional composition and ingredients.

The company’s approach to marketing is not to mislead the public about any potential health or other risks related to Tongaat Hulett products. The company’s objective is to grow its market share through product innovation and the development of highquality products as the company seeks to grow its market share in a responsible manner.

INTELLECTUAL CAPITAL

Tongaat Hulett’s intellectual property is protected through employment contracts and confidentiality agreements and/or license agreements with external parties. These agreements establish ownership of and rights to trademarks, copyright, trade secrets, innovations and inventions resulting from any dealings with the company. In the sugar operation, a portfolio of patents is managed by a knowledge management specialist in consultation with patent attorneys. Protection of patentable ideas is achieved by immediately obtaining provisional patents, with targeted national and international patenting. Tongaat Hulett holds 13 patents registered in Australia, Brasil, China, Colombia, Indonesia, India, Mauritius, Mexico, South Africa and USA. It is a proprietor of 316 registered trademarks in Australia, Botswana, Lesotho, Namibia, New Zealand, Phillipines, South Africa, South Korea, Swaziland, Taiwan and the United Arab Emirates. The company has 50 domain names registered to it.

Third party certifications

Tongaat Hulett continues to benchmark its performance against global best practices to ensure sustainable development in dealing with the broader sustainability issues incorporating SHE and food safety aspects. Operations subscribe to various

internationally-recognised management systems and/or specifications that include NOSA, OHSAS 18001, ISO 14001, ISO 9001, HACCP, FSSC 22000 and ISO 22000.

All operations are certified to either NOSA 5 Star systems or OHSAS 18001 covering occupational health and safety. Of the 19 operations, 15 are certified to the ISO 14001 environmental management system with another one currently going through a routine external surveillance review process to address issues of concern. Progress is being made to ensure that the remaining three operations are moved to the ISO 14001 system. A total of four out of five starch operations and two out of eight sugar packaging operations are certified to ISO 22000/HACCP/ FSSC 22000 food safety management systems. Plans are being implemented to ensure that all food handling operations fully subscribe to food safety management systems and therefore will achieve third party certification.

INDEPENDENT THIRD PARTY ASSURANCE

Integrated Reporting & Assurance Services (IRAS) was engaged by Tongaat Hulett to provide Independent Third Party Assurance (ITPA) over the sustainability content within Tongaat Hulett’s 2014 Integrated Report.

Based on our reviews of the Integrated Report, as well as our interviews and desktop research exercises at the group level, the information contained within this Integrated Report is deemed fair, factual and reflective of Tongaat Hulett’s adherence to AccountAbility’s AA1000AS (Type I, Moderate) principles of Inclusivity, Materiality and Responsiveness.

A comprehensive assurance statement has been submitted to Tongaat Hulett, and will be available on the company’s website www.tongaat.com.

For information about our assurance processes and/or findings, please email michael@iras.co.za.

REQUEST FOR FEEDBACK

Tongaat Hulett would like to hear from all stakeholders on their views of the 2014 Sustainability Report. The company is particularly interested in the information that was provided, information that was not included, the data reported on and the design of the report.

Please contact:

Corporate Affairs, Tongaat Hulett, PO Box 3

Tongaat, 4400, South Africa

Telephone: +27 32 439 4114

Email: sustainability@tongaat.com

GRI Index

For detailed Global Reporting Initiative

G3 sustainability reporting indicators: