Natural Capital

Environmental stewardship

Globally, natural resources are under stress and ecosystem degradation is a material issue to all businesses, given the significance of sustainable natural capital to global socio-economic prosperity. As an agricultural company, Tongaat Hulett is a major user and owner of land, biodiversity and water resources. Tongaat Hulett embraces the sustainability imperative of conducting business in an environmentally-conscious manner.

Climate change

Climate change creates risks and opportunities for the company and may ultimately lead to significant changes in the physical environments in which businesses operate. Management believes the global energy and climate challenges are best met by companies, governments and society working together. Energy demand growth will require increased energy efficiency, and the use of all available energy sources: fossil fuels, nuclear and renewable energy sources.

Given the increased focus on climate change, Tongaat Huletthas an objective of changing its emissions profile and improving energy and GHG-intensity of its operations. The generation of renewable electricity from bagasse and the blending of biofuel with petrol and diesel will help consumers to lower their GHG emissions.

The business is committed to reducing its greenhouse gas emissions by five percent per annum for the next five years and is targeting at least a 20 percent reduction by 2020 from a 2013 baseline. |

Carbon management

Climate change is integrated into the business’s company-wide risk management processes and a detailed discussion on this important topic is included in Tongaat Hulett’s latest submission to the Carbon Disclosure Project (CDP). The CDP is an independent initiative encouraging transparency on all climate changerelated issues and providing details of emissions performance. As part of the CDP process, the company conducted its fifth carbon footprint analysis which was conducted according to the Greenhouse Gas Protocol, a widely used international accounting tool. Details of the company’s actions underway are provided in the public response to the CDP (www.cdproject.net). Tongaat Hulett tracks and monitors its GHG emissions and will continue to improve the accuracy and reporting of its carbon footprint.

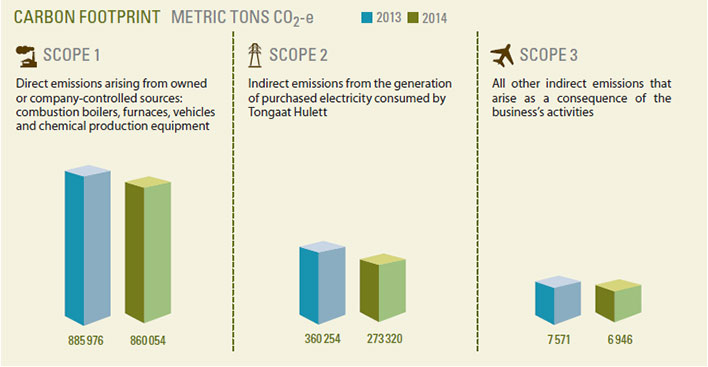

During the year, business operations emitted 860 054 metric tons CO2 equivalent (CO2-e) Scope 1 emissions. The company purchased electricity that emitted 273 320 metric tons of CO2-e. The total Scope 3 emissions were 6 946 metric tons CO2-e covering business travel, supply chain transport and distribution by third party companies. In the reporting period, employees booked nearly 2 000 business trips, flying more than 3,4 million kilometres, resulting in 703 metric tons CO2-e being emitted from business travel.

The total Scope 1, Scope 2 and Scope 3 carbon emissions for the period under review was 1 140 320 tons CO2-e and the turnover was R15, 716 billion, which equates to 73 grams of CO2 emitted per Rand generated. The GHG emissions have been verified by a third party service provider.

Total emissions from South African operations, calculated at 749 529 metric tons CO2-e, includes emissions of 393 016 metric tons CO2-e emanating from the South African sugar operations. Tongaat Hulett recently completed a study with the assistance of carbon specialists which found that the company’s sugar farms sequest carbon at a rate of 12 tons per hectare per annum from sugarcane produced. Using this rate, Tongaat Hulett’s 35 035 hectares (grown from company-owned and leased land) equates to 420 420 metric tons sequested CO2-e per annum. The South African sugar operations could benefit from the carbon capture and storage of CO2 in the growing of sugarcane if the National Treasury allows for sequested emissions to be deducted from the company’s carbon footprint.

Consequently, this part of the business should be well placed to offset a substantial part of its emissions on this basis, resulting in South African operations emitting a net 329 109 metric tons CO2-e overall. |

Energy

The imminent introduction of a suitable regulatory framework

for the provision of privately-produced alternative energy to the

national grid in South Africa could potentially result in Tongaat

Hulett expanding the business’s ability to generate electricity

from bagasse, a renewable resource produced as a co-product of

the sugar refinement process. In the short to medium term, this

would involve infrastructure development projects across the company’s sugar mills in order to more than double capacity for

energy generation from bagasse.

The imminent introduction of a suitable regulatory framework

for the provision of privately-produced alternative energy to the

national grid in South Africa could potentially result in Tongaat

Hulett expanding the business’s ability to generate electricity

from bagasse, a renewable resource produced as a co-product of

the sugar refinement process. In the short to medium term, this

would involve infrastructure development projects across the company’s sugar mills in order to more than double capacity for

energy generation from bagasse.

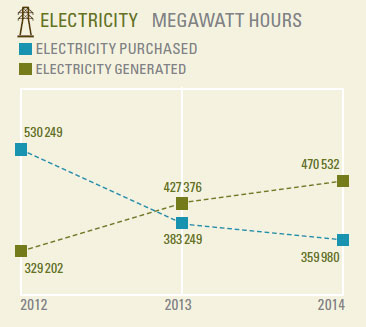

For the period to 31 March 2014, Tongaat Hulett used 784 397 MWh of electricity in all of its operations and offices. It generated 470 532 MWh from its sugar mills, predominantly from bagasse, and sold 45 930 MWh to the national grid. In the previous reporting period ended 31 March 2013, Tongaat Hulett used 774 302 MWh, generated 427 376 MWh and sold 36 323 MWh. Other sources of fuel that are used include coal (295 740 tons), diesel (12 343 725 litres), petrol (1 097 981 litres), gas (472 293 KJ) and wood.

Air quality

Sugar mills primarily burn bagasse as a fuel and, as a result, the flue gases from the boilers do not contain harmful levels of contaminants. Wet scrubbing technology is used to remove fly-ash from the flue gas to ensure that emissions meet the required air quality standard. The recent South African legislative changes to air quality standards are far more stringent and present a challenge for the sugar industry as a whole and an appropriate action plan to ensure compliance with new standards has been formulated. All South African sugar operations have submitted applications for their Air Emission License and are awaiting feedback from the relevant authority. During 2014, the milling operations have trialed the use of woodchips as a supplementary fuel option to deal with low cane throughputs periods. The trials were successful and have provided an alternative to coal-based fuel.

Some sugar mills and in particular the central sugar refinery in the Durban South Industrial Basin burn coal as a boiler fuel and therefore have a greater challenge in terms of emission reduction, as required by the recent legislative amendments. The refinery has been issued with a five year schedule trade permit which has incorporated the latest air quality standards based on its rated capacity. The revised emission targets have been based on the development of innovative process technology which will have significant energy efficiency benefits. The construction of the R18m demonstration plant to test the new proposed process technology has been completed. The project is now due for commissioning which will take place during 2014.

During 2013, the refinery initiated two projects aimed at reducing its overall carbon footprint. The first project involved the cross-haul of sugar during the milling off-season via rail, thereby reducing the impact of road transport. The second initiative was the complete replacement of the forklift fleet for sugar movement in the warehousing operations resulting in a 14 percent reduction in diesel usage.

Biodiversity and land management

External expectations around the private sector’s management of biodiversity are growing. Tongaat Hulett’s activities impact biodiversity, making agricultural and land development projects increasingly high profile and sensitive for communities, governments, investors and other interested parties. The company controls over 20 000 gross hectares of land in South Africa, of which some 8 200 developable hectares have been assessed as having high potential for conversion from agriculture to other uses at the appropriate time. This conversion is carefully managed in a coordinated and planned manner in line with broader government objectives and spatial policies. At the same time the company continues to rehabilitate currently unproductive land to agriculture in support of government’s agricultural and rural development goals and objectives, while also securing additional sugarcane supply to its mills.

Water resource management

Tongaat Hulett is involved in water partnership projects addressing locally relevant issues such as watershed protection, access to safe drinking water, sanitation, agricultural water efficiency, and education and awareness.

Management is increasingly addressing water stewardship in the context of the “water-energy-food” nexus through an integrated approach informed by the CDP Water Disclosure, the 2030 Water Resources Group (2030 WRG), and the National Water Resources Strategy released by the South African Department of Water Affairs. The business is a signatory of the UN Global Compact CEO Water Mandate and is committed to effective water resource management throughout its operations.

The company has a Water Policy in place which documents Tongaat Hulett’s approach to key water management elements, including effective use of water resources, local water resource optimisation and protection. |

The company continues to identify opportunities for water

recycling, efficient use and responsible wastewater disposal. Sugar

mills in South Africa are net producers of water due to the fact

that the sugarcane plant comprises approximately 70 percent

water. Most of the sugarcane cultivated in South Africa is

dependent on natural rainfall, while operations in Mozambique,

Swaziland and Zimbabwe practice large-scale irrigation via

purpose-built canal systems with water being extracted from

rivers. The management of these canals and irrigation systems is

in keeping with the highest agronomy and safety standards.

The company continues to identify opportunities for water

recycling, efficient use and responsible wastewater disposal. Sugar

mills in South Africa are net producers of water due to the fact

that the sugarcane plant comprises approximately 70 percent

water. Most of the sugarcane cultivated in South Africa is

dependent on natural rainfall, while operations in Mozambique,

Swaziland and Zimbabwe practice large-scale irrigation via

purpose-built canal systems with water being extracted from

rivers. The management of these canals and irrigation systems is

in keeping with the highest agronomy and safety standards.

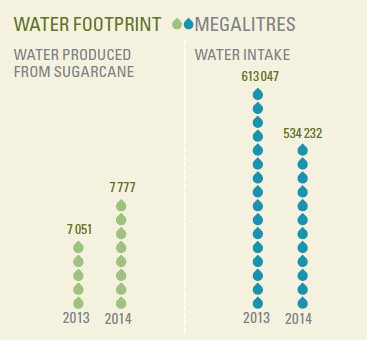

The input water sources include water abstracted from rivers, water available in sugarcane and water purchased from municipal sources. Most sugar mills operate in remote locations and therefore assist in the provision of potable water to local communities. For the reporting period, the total water input was 514 232 Ml of which 7 777 Ml was produced from sugarcane and 8 352 Ml was supplied to communities or sold to local municipalities.

Effluent

Subsequent to the ‘zero effluent` philosophy that has been adopted by several operations to minimise the quantity of liquid effluent leaving each mill or plant, most of Tongaat Hulett’s sugar mills recycle and re-use water within the factories, while the remaining effluent undergoes biological treatment (aerobic and anaerobic) to reduce its chemical oxygen demand to acceptable levels before being discharged in accordance with the relevant environmental requirements. The remaining mills are developing environmental management programmes to adopt best practices and ensure legal compliance as a minimum. Water that is produced as part of the sugar milling process is largely used for the irrigation of sugarcane on adjacent estates and effluent produced at the central sugar refinery is disposed of into the municipal sewer for treatment, and both the quantity and quality thereof is monitored to ensure compliance with the relevant specifications.Waste management

Some company operations have re-engineered and refined services in order to reduce waste and increase resource productivity and these initiatives have yielded new revenue streams from the sale, exchange and recycling of waste products. A significant increase in recycled material volumes was noted for this reporting period. Some of the new practices implemented include the recycling of cane spillage from roadways back into farming.

The increase in hazardous waste volumes is mainly attributed

to the re-classification of boiler ash at Triangle and Hippo

Valley. The residual chemical content in boiler ash has resulted

in the `hazardous’ classification. This is most likely linked to the

source of coal being used at these two operations. During the

reporting period, 12 824 tons of general waste (2013: 11 436 tons),

2 803 tons of scrap metal waste (2013: 4 152 tons) and 4 359 tons

of hazardous waste (2013: 3 084 tons) was generated and

disposed of in accordance with applicable legislation.

The increase in hazardous waste volumes is mainly attributed

to the re-classification of boiler ash at Triangle and Hippo

Valley. The residual chemical content in boiler ash has resulted

in the `hazardous’ classification. This is most likely linked to the

source of coal being used at these two operations. During the

reporting period, 12 824 tons of general waste (2013: 11 436 tons),

2 803 tons of scrap metal waste (2013: 4 152 tons) and 4 359 tons

of hazardous waste (2013: 3 084 tons) was generated and

disposed of in accordance with applicable legislation.

Environmental compliance

During the year, the company dealt with a number of concerns raised by affected stakeholders surrounding its operations. There were no material incidents or non-monetary sanctions for noncompliance with applicable environmental regulations during the year under review. The established community liaison forums between Tongaat Hulett and interested parties continue to address environmentally-related complaints. Below is a summary of how the issues were addressed and resolved:

- The Maidstone mill in Tongaat was issued with a directive by the municipal official in September 2013 relating to the overflow of effluent during a sludge removal activity at the effluent dam. The mill was asked to develop a plan for effective management of the effluent dam. This plan was submitted and acknowledged by the regulatory authority. The mill continues to proactively engage with local communities and the relevant authorities on matters related to effluent irrigation. Several short-term initiatives have been put into place to deal with community concerns.

- The Department of Environmental Affairs (DEA) issued a fine to Tongaat Hulett for disturbing virgin land in the KwaMthethwa traditional leadership area where the cane and rural development unit (CRDU) was operating. While it had been acknowledged that Tongaat Hulett’s agriculture operations caused some disturbance on virgin land, management took a decision to appeal against the level of the fine considering an existing partnership involving Tongaat Hulett, the DEA and the KwaMthethwa Traditional Council. An appeal decision has since been received from the DEA, in which the extent of the original fine was significantly reduced. In the interim, efforts continue to be directed at avoiding tampering with virgin land during agriculture operations. Visit Tongaat Hulett website at www.tongaat.com for more detail.

- A total of 50 complaints (48 - level 1 and two - level 2) were recorded during the year.

The following is a summary of how the more severe (level 2) complaints were addressed and resolved:

- The Developments operation received a complaint regarding the pruning of trees at the business’s office. The incident, which attracted local media attention, was addressed by the operation.

- The Starch milling operations received complaints relating to effluent and odour from process operations. Corrective action was taken to address all matters that were raised and the measures taken included the submission of an environmental management plan and the upgrading of process operations to deal with these complaints.